Introduction

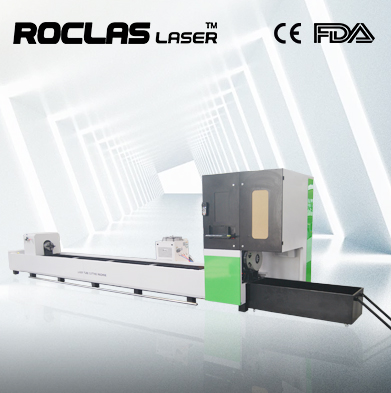

Laser engraving stainless steel is a highly precise and efficient method for creating permanent markings, decorative designs, or functional identifiers on metal surfaces. Whether for industrial applications, branding, or artistic purposes, a high-quality fiber laser cutting and engraving machine ensures superior results. Roclas, a leading brand in CNC engraving technology, offers advanced solutions that deliver unmatched precision, speed, and durability.

Why Choose Laser Engraving for Stainless Steel?

Stainless steel is a durable, corrosion-resistant material widely used in industries such as aerospace, automotive, medical devices, and jewelry. Traditional engraving methods like mechanical etching or chemical processes can be time-consuming and less precise. In contrast, fiber laser engraving provides

- High Precision – Lasers can create intricate designs with micron-level accuracy.

- Permanent Markings – Unlike ink or paint, laser-engraved marks resist wear, chemicals, and extreme conditions.

- No Contact Process – The laser beam doesn’t physically touch the material, reducing tool wear and contamination.

- Fast & Efficient – Automated laser systems like Roclas CNC machines enable high-speed production with minimal setup time.

How Does Laser Engraving Stainless Steel Work?

Fiber lasers use a concentrated beam of light to vaporize or oxidize the surface of stainless steel, creating a contrast between the engraved area and the base material. The process involves

1. Material Preparation – Clean the stainless steel surface to remove oils or residues.

2. Laser Settings Adjustment – Adjust power, speed, and frequency based on the desired depth and contrast.

3. Engraving Process – The laser beam moves across the material following a pre-programmed design.

4. Post-Processing (Optional) – Some applications may require polishing or coating for enhanced aesthetics.

Best Practices for Laser Engraving Stainless Steel

To achieve the best results with a Roclas fiber laser engraving machine, follow these tips

- Use High-Quality Lasers – Roclas machines feature high-power fiber lasers (20W-100W+) for deep and clean engravings.

- Optimize Parameters – Lower power and higher speed work well for fine markings, while higher power ensures deeper engravings.

- Ensure Proper Focus – A well-calibrated focal point prevents blurry or inconsistent marks.

- Test on Scrap Material – Always run a test engraving to fine-tune settings before working on the final piece.

Applications of Laser-Engraved Stainless Steel

- Industrial Part Marking – Serial numbers, barcodes, and logos for traceability.

- Medical & Surgical Tools – Permanent identification for sterilization compliance.

- Jewelry & Custom Gifts – Personalized engravings for rings, bracelets, and plaques.

- Architectural & Signage – Decorative panels, nameplates, and corporate branding.

Why Choose Roclas for Laser Engraving?

Roclas CNC laser engraving machines stand out due to

✔ Advanced Fiber Laser Technology – High-speed, high-precision engraving.

✔ User-Friendly Software – Compatible with industry-standard design programs.

✔ Robust Build Quality – Designed for industrial durability and long-term performance.

✔ Excellent Customer Support – Expert guidance for setup, operation, and maintenance.

Conclusion

Laser engraving stainless steel is a versatile and efficient process, ideal for both industrial and creative applications. With Roclas CNC laser machines, businesses and hobbyists can achieve professional-grade results with ease. Whether you need durable part markings or elegant custom designs, Roclas delivers precision, speed, and reliability.

Upgrade your engraving capabilities with Roclas today! 🚀