Introduction

co2 laser cutting machines are versatile tools widely used in industries for precision cutting, engraving, and marking. At Roclas, we specialize in high-performance CO2 laser machines that deliver exceptional results across various materials. If you're wondering what materials a CO2 laser can cut, this guide will explore the capabilities of CO2 lasers and highlight the best materials for laser processing.

How CO2 Laser Cutting Works

A CO2 laser cutter uses a high-powered infrared laser beam generated by exciting carbon dioxide gas. The laser beam is focused through a lens, vaporizing or melting materials with extreme precision. The machine’s CNC system ensures accurate cuts, making it ideal for intricate designs and industrial applications.

Materials Suitable for CO2 Laser Cutting

1. Wood & Plywood

CO2 lasers excel at cutting and engraving wood, including softwoods, hardwoods, MDF, and plywood. They produce clean edges without splintering, making them perfect for furniture, signage, and decorative art.

2. Acrylic & Plastics

Acrylic is one of the best materials for CO2 laser cutting, as it melts smoothly, leaving a polished edge. Other plastics like PMMA, polycarbonate (with caution), and ABS can also be processed efficiently.

3. Paper & Cardboard

Laser cutting is widely used in packaging and paper crafts. CO2 lasers provide precise cuts without tearing, making them ideal for intricate designs in invitations, packaging prototypes, and displays.

4. Leather & Fabric

From fashion to upholstery, CO2 lasers cut leather, synthetic fabrics, and natural textiles with high precision. They prevent fraying and allow for detailed patterns in garments, shoes, and accessories.

5. Rubber & Foam

Industrial rubber sheets and foam materials (EVA, neoprene) can be cleanly cut for gaskets, seals, and cushioning applications.

6. Glass & Ceramics (Engraving Only)

While CO2 lasers cannot cut glass or ceramics deeply, they are excellent for surface engraving, creating frosted designs on glassware or ceramic tiles.

7. Metals (With Limitations)

Pure CO2 lasers struggle with metals due to high reflectivity, but with anodized or coated metals, they can mark or lightly engrave surfaces. For metal cutting, fiber lasers (like Roclas’ fiber laser machines) are more effective.

Materials to Avoid with CO2 Lasers

- PVC & Vinyl – Releases toxic chlorine gas when cut.

- Polycarbonate (Thick Sheets) – Can discolor or crack.

- Metals (Uncoated) – Reflects the laser beam, risking damage to the machine.

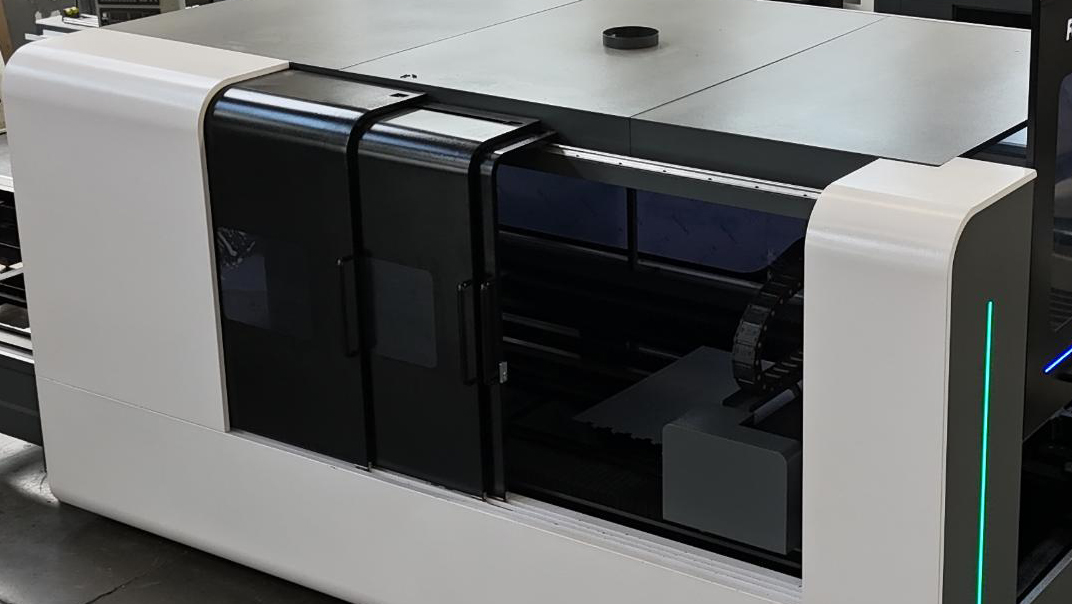

Why Choose Roclas CO2 Laser Machines?

At Roclas, we design CO2 laser cutters for superior performance, durability, and precision. Our machines feature

- High-power laser tubes for faster cutting speeds.

- Advanced cooling systems for prolonged operation.

- User-friendly software compatibility (LightBurn, CorelDraw).

- Rigorous safety standards to protect operators.

Conclusion

CO2 laser cutting is a powerful technology for non-metallic materials like wood, acrylic, leather, and more. For metals, consider Roclas’ fiber laser machines, which offer deeper cuts and higher efficiency. Whether you're in manufacturing, arts, or prototyping, Roclas provides the perfect laser solution for your needs.