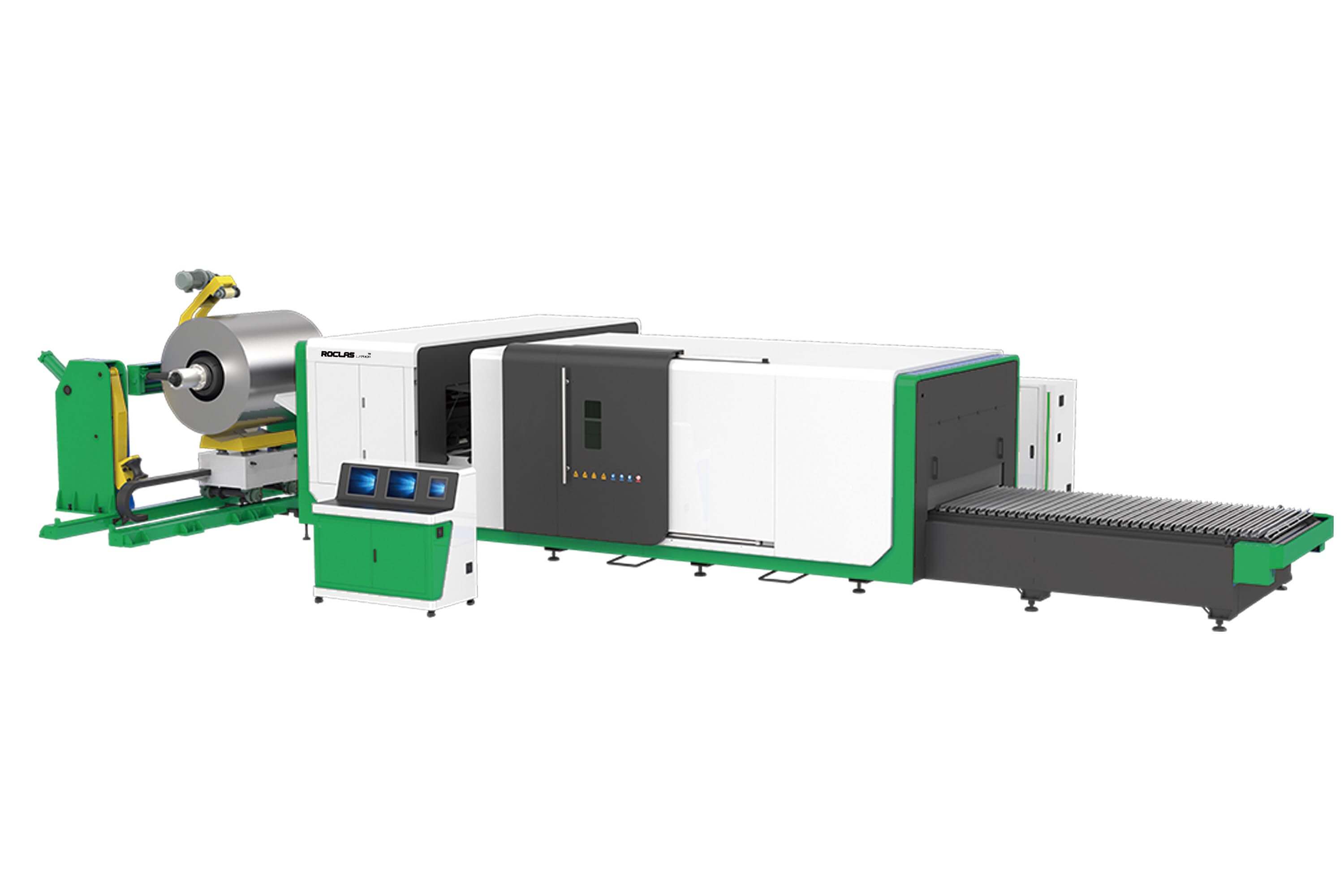

In modern industrial manufacturing, fiber laser cutting technology has redefined precision standards with its micron-level accuracy. Roclas, as a leader in this field, achieves cutting tolerances as tight as ±0.05mm through an integrated system of optical engineering, mechanical innovation, and AI-driven control. This paper explores the core technologies behind its exceptional performance.

Roclas employs proprietary single-mode fiber lasers with beam quality (M²) below 1.1, ensuring a near-perfect Gaussian beam profile. This reduces energy divergence during transmission, maintaining focus spot diameters as small as 20μm at optimal working distances.

The dynamic collimation system incorporates:

Motorized zoom lenses with 0.1μm positioning resolution

Real-time curvature sensors for material thickness compensation

Air-assisted nozzle design preventing lens contamination

Unlike traditional ball bearings, Roclas machines use hydrostatic guideways:

Eliminates mechanical friction for infinite motion smoothness

Achieves 0.1μm repeatability in XYZ axes

Vibration damping reduces harmonic disturbances by 80%

The granite base and liquid cooling system maintain 0.2°C/hour temperature stability, counteracting thermal expansion effects that typically cause 3μm/meter dimensional drift in conventional machines.

Machine learning algorithms analyze:

Material reflection coefficients

Gas flow dynamics

Kerf width patterns

Adjusting power/pulse parameters every 0.01 second for consistent edge quality.

LIDAR sensors detect:

Sheet warpage (compensation range ±2mm)

Tool wear (prediction accuracy 95%)

Environmental humidity (0.1% RH sensitivity)

Roclas' precision stems from its holistic approach integrating quantum optics, tribology-free mechanics, and adaptive intelligence. As Industry 4.0 demands tighter tolerances, these innovations set new benchmarks for precision manufacturing.