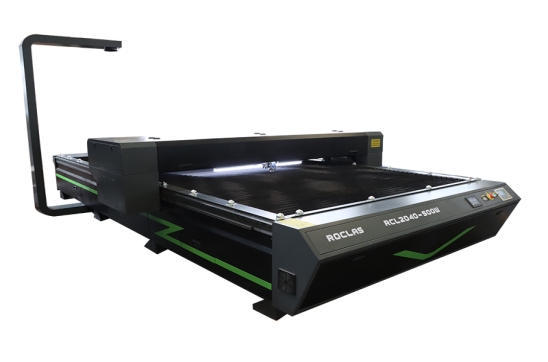

| Parameter | RCL2040 |

| X,Y,Z Traveling | 2000*4000mm |

| Laser power | 500W |

| Working area | 2000*4000mm |

| Laser type | Sealed Co2 glass laser tube |

| Cooling mode | Water Cooling |

| Repeat positioning accuracy | ±0.02mm |

| Laser Source | Raytools |

| Laser Head | Au3tech |

| Cutting thickness | 0-25mm |

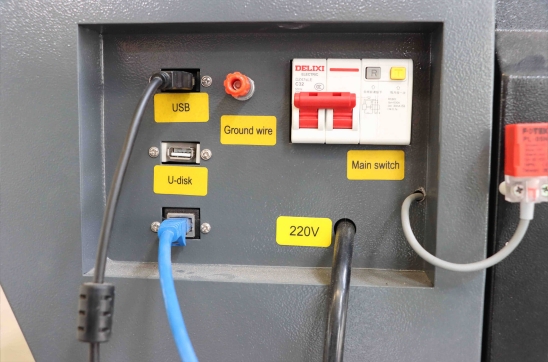

| Working Voltage | 110 - 220V:10%,50- 60Hz |

| Max speed | 40m/min |

| Max acceleration | 0.6G |

| Support graphic format | DST,PLT,BMP,DXF |

| Dimensions | 4950*2400*1300mm |

| Weight | 2400KG |

Provide multilingual display panel, which is convenient for every country customer to use.

Simultaneously conduct engraving and cutting

Fast operating speed ,easy to use,low cost,reliable engraving effects and burr-free cut edges.

The engraving depth can be easily adjusted with high precision

True "all-material" processing capabilities: A single machine integrates a CO2 laser (for non-metals) and a fiber laser/other metal processing unit (for metals), achieving comprehensive coverage for metals and non-metals (such as wood, acrylic, and leather), encompassing a wide range of applications.

Seamless process integration, one-stop prototyping: For parts requiring a combination of processes (such as acrylic logos on metal substrates), metal cutting, non-metal cutting, and surface engraving can be completed sequentially at the same station, eliminating the need for equipment changes, ensuring precision and streamlining the process.

Leveraging the advantages of various processing methods

Extremely flexible production and rapid market response: From hard metal to soft leather, from batch cutting to personalized custom engraving, a single machine can handle it all. This allows businesses to handle diverse, small-batch orders with exceptional adaptability.

Significant savings in equipment investment and factory space: Compared to purchasing separate dedicated metal cutting machines, non-metal laser machines, and knife cutters, a single hybrid cutting machine saves significant procurement costs and valuable floor space. 6. Intelligent software control, easy operation: Typically controlled by a unified software system, it intelligently recognizes different patterns and automatically assigns the corresponding processing tool (laser), reducing the operator's learning curve and technical reliance.

Low cost of use: No physical tool wear occurs during the processing process; the only consumables are the laser tube and conventional lenses, reducing long-term maintenance and replacement costs.

Perfect combination of non-contact processing and mechanical cutting: Laser processing is contactless and stress-free, making it suitable for precision components.

Significantly improves manufacturing efficiency for complex products.

Strong market competitiveness and brand image: With this "all-round" machine, companies can provide customers with a one-stop solution from design to finished product, significantly enhancing their technical strength and market competitiveness.

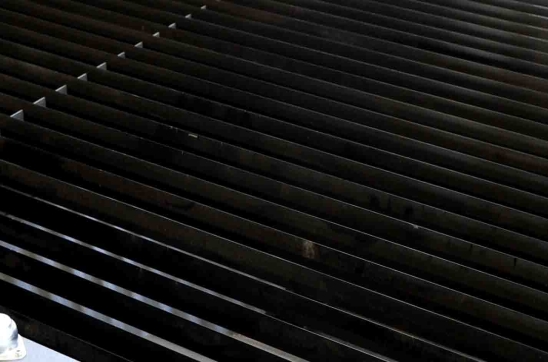

The CO2 Hybid cutting machine integrates cutting capabilities for both metal and non-metal materials.

It can cut carbon steel and stainless steel.

It can also cut non-metal materials such as rubber, plastic, and plywood.

It offers fast cutting speeds and high precision.

It is easy to operate and can be used after a brief training session.

Non-contact processing: Laser cutting is contactless and does not cause mechanical damage to the surface of the material.

Power options range from 150W to 600W.

Sizes can be customized to meet your needs.

Suitable for advertising signage, crafts, souvenirs, furniture and toys, signage, and mechanical parts.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

What is the weight limit of tubes that a tube cutting machine can handle?

Tube cutting capacity depends on model. ROCLAS® MACHIN lasers typically support tubes up to 200–300 kg, depending on length and diameter.

Will cutting certain materials damage the laser?

Avoid cutting highly reflective or overly thick materials beyond the machine’s spec. ROCLAS® MACHINERY lasers include protective settings to minimize damage risks during processing.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

How does a fiber laser machine achieve batch processing?

ROCLAS® MACHINERY fiber lasers support batch processing via auto-loading systems and programmed nesting, improving throughput for large production runs.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about co2 laser cutting machine 500W,Roclas is a professional co2 laser cutting machine 500W manufacturer with 15 years of production experience,Roclas has established itself as a leader in the co2 laser cutting machine 500W industry, delivering high-quality products best co2 laser cutting machine 500W price and services to meet a diverse range of customer needs.

Previous:Not

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.