When it comes to precision metal cutting, Roclas Fiber laser cutting machines deliver performance you can trust. As an industry leader with years of dedicated research and manufacturing experience, we understand what modern workshops truly need – equipment that combines reliability with smart innovation.

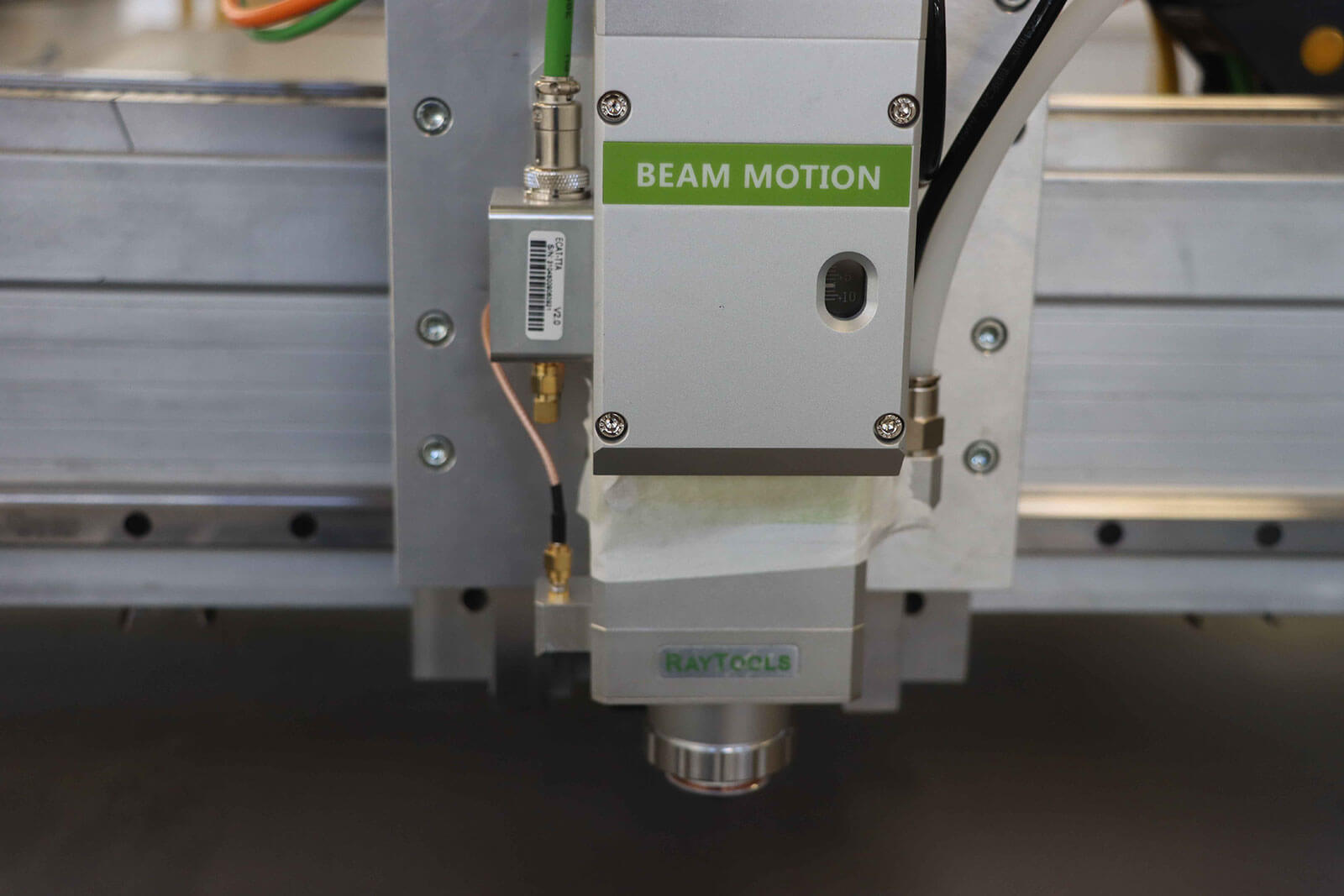

Our fiber laser systems are designed to handle both sheet metal and tube cutting with remarkable efficiency. The secret lies in our continuous technological improvements. Unlike generic suppliers, we maintain an in-house R&D team consisting of seasoned experts who constantly refine laser beam quality, motion control systems, and software integration. This ensures your investment stays relevant as technology evolves.

What sets Roclas apart is our comprehensive product ecosystem. Beyond standard laser cutters, we offer integrated solutions including laser welders, marking systems, and hybrid CO₂ machines – all developed with the same philosophy of precision engineering. Our 5-axis machining centers and CNC plasma cutters further expand your production capabilities. Every machine undergoes rigorous testing to meet international standards before shipment.

For businesses seeking long-term partnerships, we provide more than just hardware. Our technical support team assists with installation, operator training, and maintenance planning. Flexible configurations allow customization according to your specific material types and production volumes. Whether you're processing stainless steel for architectural components or aluminum for automotive parts, we'll recommend the optimal power rating and cutting bed size.

The real-world results speak for themselves. Workshops using Roclas equipment report significant reductions in material waste and energy consumption compared to traditional methods. Faster piercing speeds and smoother edge finishes mean you can take on more complex orders with confidence. Our clients particularly appreciate the intuitive touchscreen interfaces that simplify operation without compromising advanced functionality.

Upgrading your fabrication capabilities shouldn't be a gamble. With Roclas, you're choosing proven German-inspired engineering backed by localized service networks. We invite you to visit our demonstration facility or arrange material testing with your actual workpieces. Let's discuss how our fiber laser solutions can elevate your production line – because when your business grows, our success grows too.