| Cutting Range Selection | 3m*1.5m/4m*2m/6m*2m/6m*2.5m |

| Laser Output Power | 500w-6000w |

| Workbench Axial Accuracy | +0.03mm |

| Workbench Repeat Accuracy | +0.02mm |

| Power Requirements | 380V50Hz |

| Total Power Protection Leve | IIP54 |

Industrial grade heavy-duty steel structure design,CNC five-face machining center processing,to ensure machine tool accuracy and stability.

Using France Schneider,Japan SMC,Yade electric equipment and Germaniguscable.

Imported servo drive system and imported reducer,fast running speed and strongstability.

Taiwan's guide rails and high-precision grinding racks to ensure long-term machiningaccuracy.

Fully functional and easy to operate with professional laser cutting control system.

1.Simple operating system, to realize rapid cutting on the shape what you want on the metal material, like Steel, Iron, Aluminum Plate, Carbon steel, Stainless steel, Cooper, and galvanized sheet .

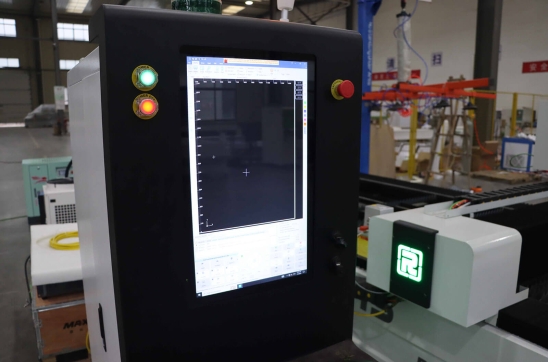

2.Independent control cabinet

1) Dust proof: all electrical components and laser sources are built in an independent control cabinet to prevent dust pollution.

2) Automatic thermostat: equipped with an automatic constant temperature air conditioner, which can prevent the damage to the components due to the high temperature.

3.Professional Operating system: Easy to use, Powerful functions, Complete cutting process, debugging easily, Real-time alarm, stable and reliable

4.AutoMatch Cutting Parameter: Through visual comparison of sample parts and cutting parameter automatch to enhance cutting quality, and reduce labor costs.

5.It adopts high-performance bus servo motors to achieve the absolute leading dynamic performance (compared with similar products in the market). Significantly improving processing efficiency to ensure that every second you invest is creating value6.Suitable for stainless steel, carbon steel, aluminum alloy, titanium alloy, galvanized steel, galvanized plate, copper and other metals.

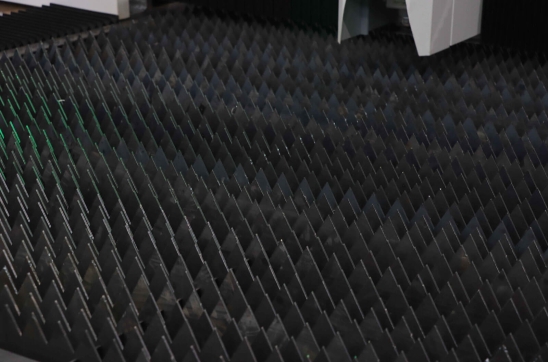

7.The cut surface is smooth and burr-free, with high precision, fast speed, narrow cutting kerf, minimal heat-affected zone, and no scratches on the workpiece during laser cutting, and no mechanical deformation of the workpiece

8.Professional nesting and typesetting software is highly integrated with professional laser cutting system, with intelligent graphic typesetting, automatic edge-finding cutting and sharp corner smoothing functions, which can realize high-speed perforation and high-speed scanning and cutting of array graphics.

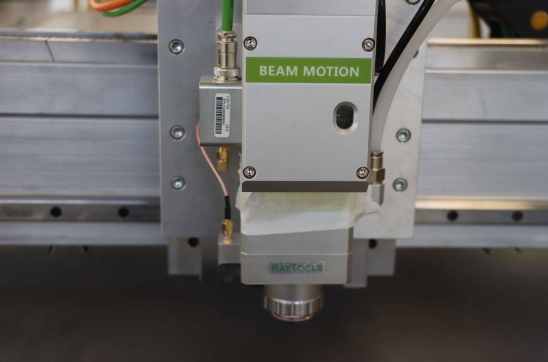

9.The laser cutting head is equipped with a fully automatic focusing function, which greatly shortens the perforation time compared to ordinary cutting heads. It is particularly suitable for high-speed cutting of thicker plates.

10. With power failure memory function, back-off cutting function, automatic fault alarm, emergency stop function, automatic display of fault content

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

Will cutting certain materials damage the laser?

Avoid cutting highly reflective or overly thick materials beyond the machine’s spec. ROCLAS® MACHINERY lasers include protective settings to minimize damage risks during processing.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

Four functions of a four-in-one welding machine:

ROCLAS® MACHINERY four-in-one machines typically integrate welding, cutting, cleaning, and weld seam cleaning — offering a complete metal fabrication solution in one unit.

How to choose a laser machine for cutting coated sheet metal parts?

When cutting coated metals, ROCLAS® MACHINERY recommends using high-peak-power lasers with optimized pulse settings to prevent coating-related damage and ensure clean cuts.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

Can the fiber laser machine bed be manufactured in a customized way?

The bed structure of ROCLAS® MACHINERY fiber laser machines is manufactured with high-strength welding and precision machining, ensuring stability even for heavy-duty cutting.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Fiber laser cutting machine,Roclas is a professional Fiber laser cutting machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Fiber laser cutting machine industry, delivering high-quality products best Fiber laser cutting machine price and services to meet a diverse range of customer needs.

Previous:Laser Marking Machine

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.