| Laser power | 20W/30W/50W/100W |

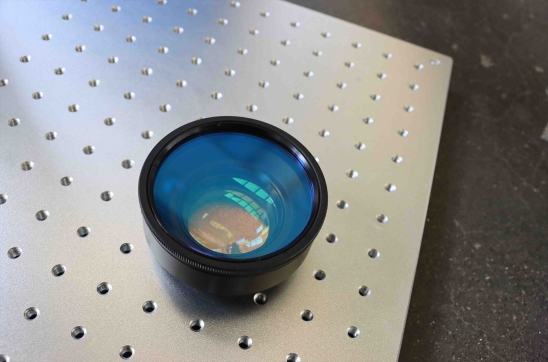

| Laser wavelength | 1064nm |

| Beam quality | M2<2 |

| Control software | Ezcad |

| Marking depth | ≤0.3mm |

| Marking speed | ≤7000mm/s |

| Minimum line width | 0.01mm |

| Minimum character | 0.5mm |

| Marking Size | 110*110mm |

| Power | <500W |

| Working voltage | 110V/220V |

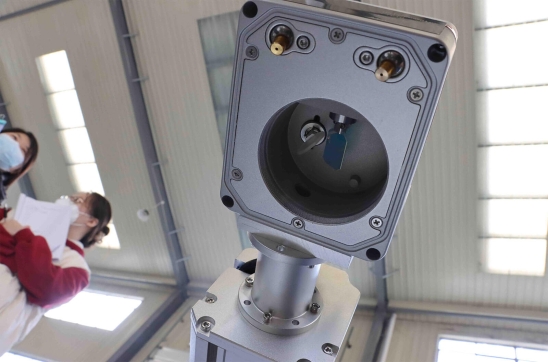

| Cooling way | Air cooling |

| Ambient operating temperature | 15°C-35 |

| Graphic file format | PLI, DXF,AI, BMP,JPG |

| Weight | 48KG |

| Machine size | 80*52*58CM |

The operation is simple and easy to use, and the processing speed is fast, 6-8 times that of traditional marking machines.

Applicable materials:Applicable various metal, such as silver, alloy, aluminum, stainless steel, copper etc, and some non-metal materials, such asPVC,PC, black acrylic.

Applicable industry:They are widely applying for electronic, jewelry, automobiles, communication products, plastic buttons, IC etc.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

Will cutting certain materials damage the laser?

Avoid cutting highly reflective or overly thick materials beyond the machine’s spec. ROCLAS® MACHINERY lasers include protective settings to minimize damage risks during processing.

How to choose a laser machine for cutting coated sheet metal parts?

When cutting coated metals, ROCLAS® MACHINERY recommends using high-peak-power lasers with optimized pulse settings to prevent coating-related damage and ensure clean cuts.

Working principle of CO2:

CO2 lasers generate beams by exciting CO2 gas. ROCLAS® MACHINERY CO₂ laser machines offer reliable engraving and cutting for non-metal materials with stable performance.

How to set up the laser machine's automatic lubrication pump?

The laser machine's automatic lubrication pump (on ROCLAS® MACHINERY models) should be set according to usage frequency to ensure smooth motion system operation.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

Four functions of a four-in-one welding machine:

ROCLAS® MACHINERY four-in-one machines typically integrate welding, cutting, cleaning, and weld seam cleaning — offering a complete metal fabrication solution in one unit.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

The laser machine will have reserved N2 and O2 gas lines.

The laser machine will have reserved N2 and O2 gas lines for high-speed, high-quality cutting of stainless steel and other metals.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Laser Marking Machine,Roclas is a professional Laser Marking Machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Laser Marking Machine industry, delivering high-quality products best Laser Marking Machine price and services to meet a diverse range of customer needs.

Previous:Fiber laser cutting machine

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.