| Cutting Range Selection | 3m*1.5m/4m*2m/6m*2m/6m*2.5m |

| Laser Output Power | 500w-6000w |

| Workbench Axial Accuracy | +0.03mm |

| Workbench Repeat Accuracy | +0.02mm |

| Power Requirements | 380V50Hz |

| Total Power Protection Leve | IIP54 |

Industrial grade heavy-duty steel structure design,CNC five-face machining center processing,to ensure machine tool accuracy and stability.

Using France Schneider,Japan SMC,Yade electric equipment and Germaniguscable.

Imported servo drive system and imported reducer,fast running speed and strongstability.

Taiwan's guide rails and high-precision grinding racks to ensure long-term machiningaccuracy.

Fully functional and easy to operate with professional laser cutting control system.

This fully integrated machine combines the host, electric cabinet, control system, laser source into a single unit. It not only optimizes workshop space, but also significantly improves utilization.

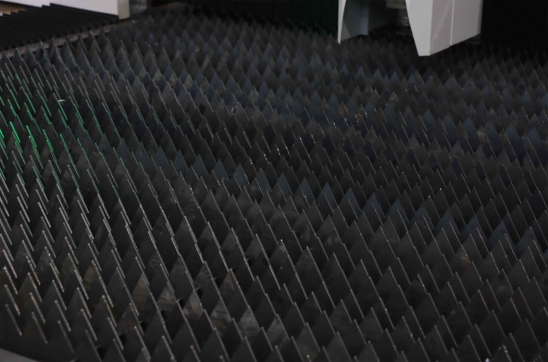

High Strength Machine Bed, adopting 600'C high temperature annealing treatment, with integrated machine rigidity. The overall mechanical structure has small deformation and low vibration, ensuring cutting accuracy

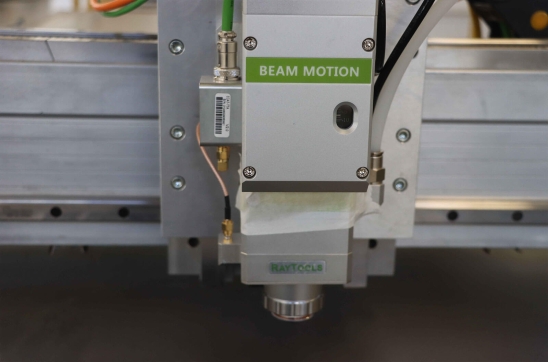

Strong Aviation Aluminum Beam: High accuracy, good toughness. Light weight, corrosion resistance. Anti-oxidation, low density. Faster processing speed.

High Precision Rack and Pinion: High precision, long life, can provide rigorous support for quenching helical gears and grinding helical gears, so that the load drive structure is compact, can effectively reduce the driving torque.

Unique exhaust structure removes smoke, dust, and heat: Smoke and dust removal is improved by over 30%, with excellent sealing, intelligent monitoring, easy maintenance, and low smoke and environmental protection.

New bus system offers flexible applications: Cutting efficiency is increased by over 20%, ensuring stability and reliability, meeting the needs of complex, high-performance applications and satisfying the demands of customers across various industries.

7.The core components adopt well-known high-end brands, with superior configuration performance, high precision, good stability, extremely low failure rate and long service life.

Intelligent laser cutting head, core optical technology, dynamic temperature control system, and intelligent perforation monitoring ensure high-speed and efficient cutting of various metal materials

It can cut various metal plates and is mainly used for fast cutting of stainless steel, carbon steel, manganese steel, galvanized plates, rare metals and other materials.

It is widely used in kitchen appliances, sheet metal chassis and cabinets, mechanical equipment, lighting hardware, advertising signs, auto parts, display equipment, various metal products, sheet metal cutting and processing and other industries.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

How does a fiber laser machine achieve batch processing?

ROCLAS® MACHINERY fiber lasers support batch processing via auto-loading systems and programmed nesting, improving throughput for large production runs.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

Four functions of a four-in-one welding machine:

ROCLAS® MACHINERY four-in-one machines typically integrate welding, cutting, cleaning, and weld seam cleaning — offering a complete metal fabrication solution in one unit.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

Will cutting certain materials damage the laser?

Avoid cutting highly reflective or overly thick materials beyond the machine’s spec. ROCLAS® MACHINERY lasers include protective settings to minimize damage risks during processing.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

Working principle of CO2:

CO2 lasers generate beams by exciting CO2 gas. ROCLAS® MACHINERY CO₂ laser machines offer reliable engraving and cutting for non-metal materials with stable performance.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Fiber laser cutting machine,Roclas is a professional Fiber laser cutting machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Fiber laser cutting machine industry, delivering high-quality products best Fiber laser cutting machine price and services to meet a diverse range of customer needs.

Previous:Not

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.