| Cutting Area | 1500*300mm*2 |

| Cutting Speed | 0-40000mm/min |

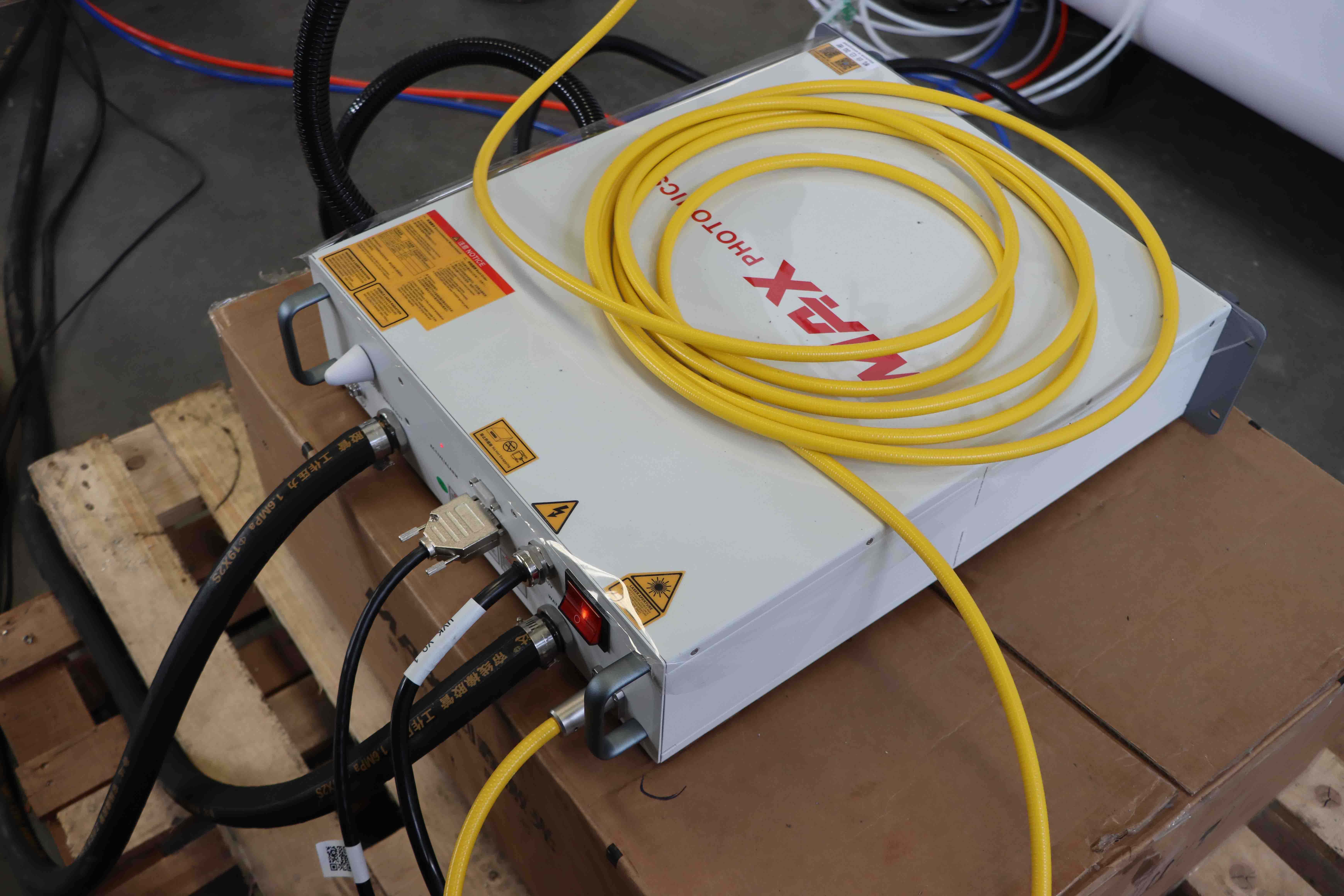

| Laser Source | MAX |

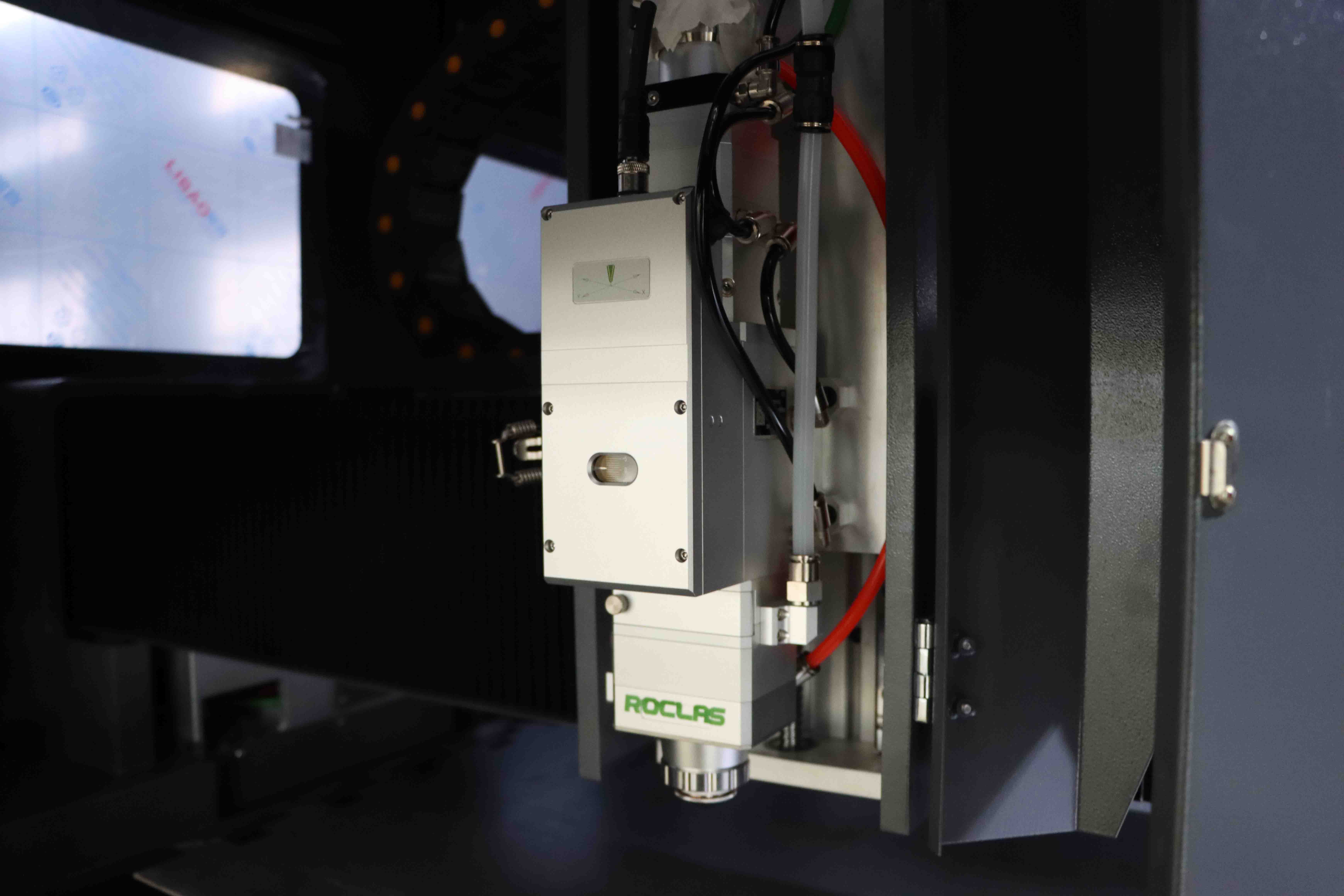

| Laser Head | Raytools |

| Driving System | Leadshine servo motor |

| Cooling System | Water Cooling |

| Laser Power | 3000-12000W |

| Cutting Thickness | 0-30mm |

| Gross Power | 21KW |

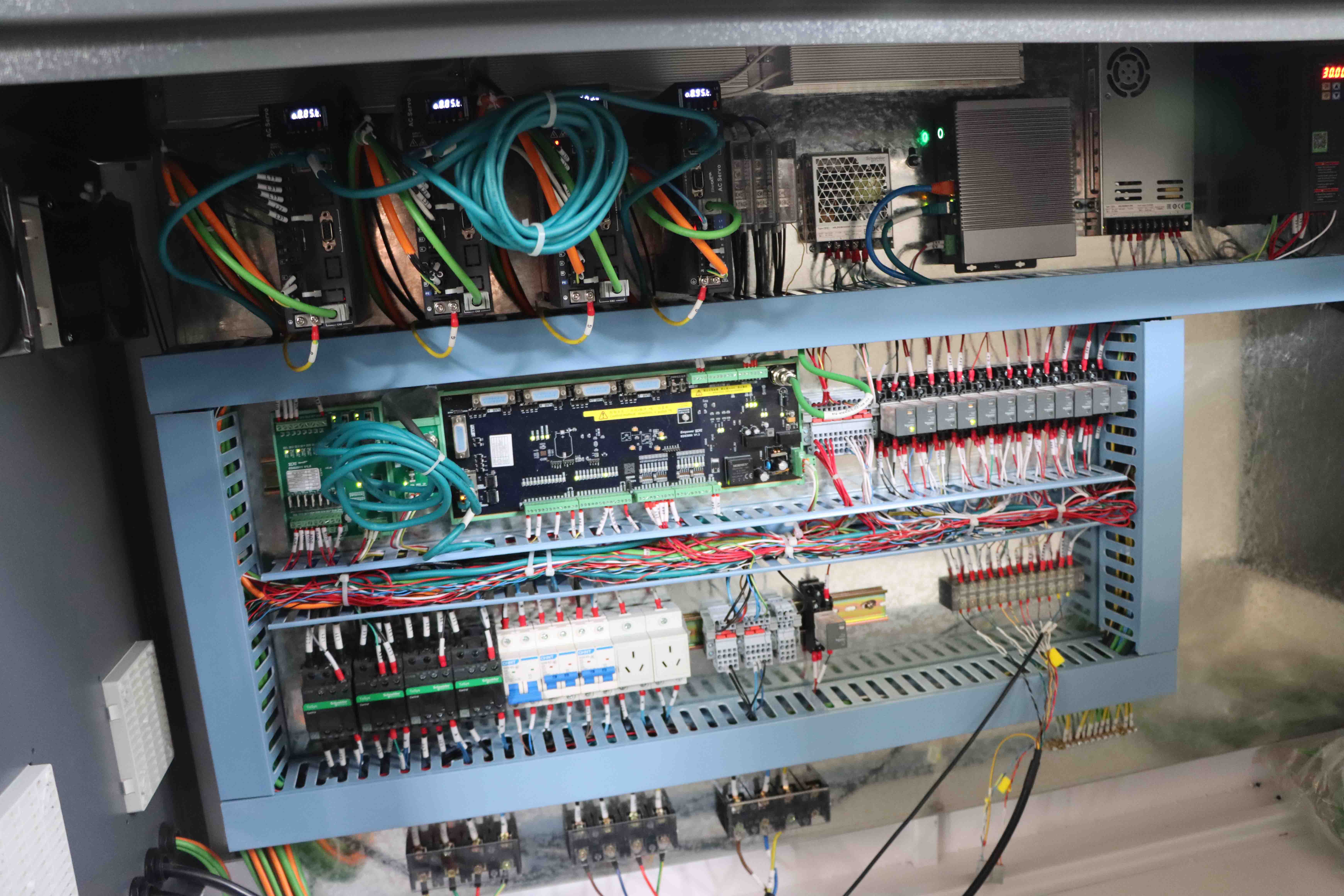

| Control System | Raytools |

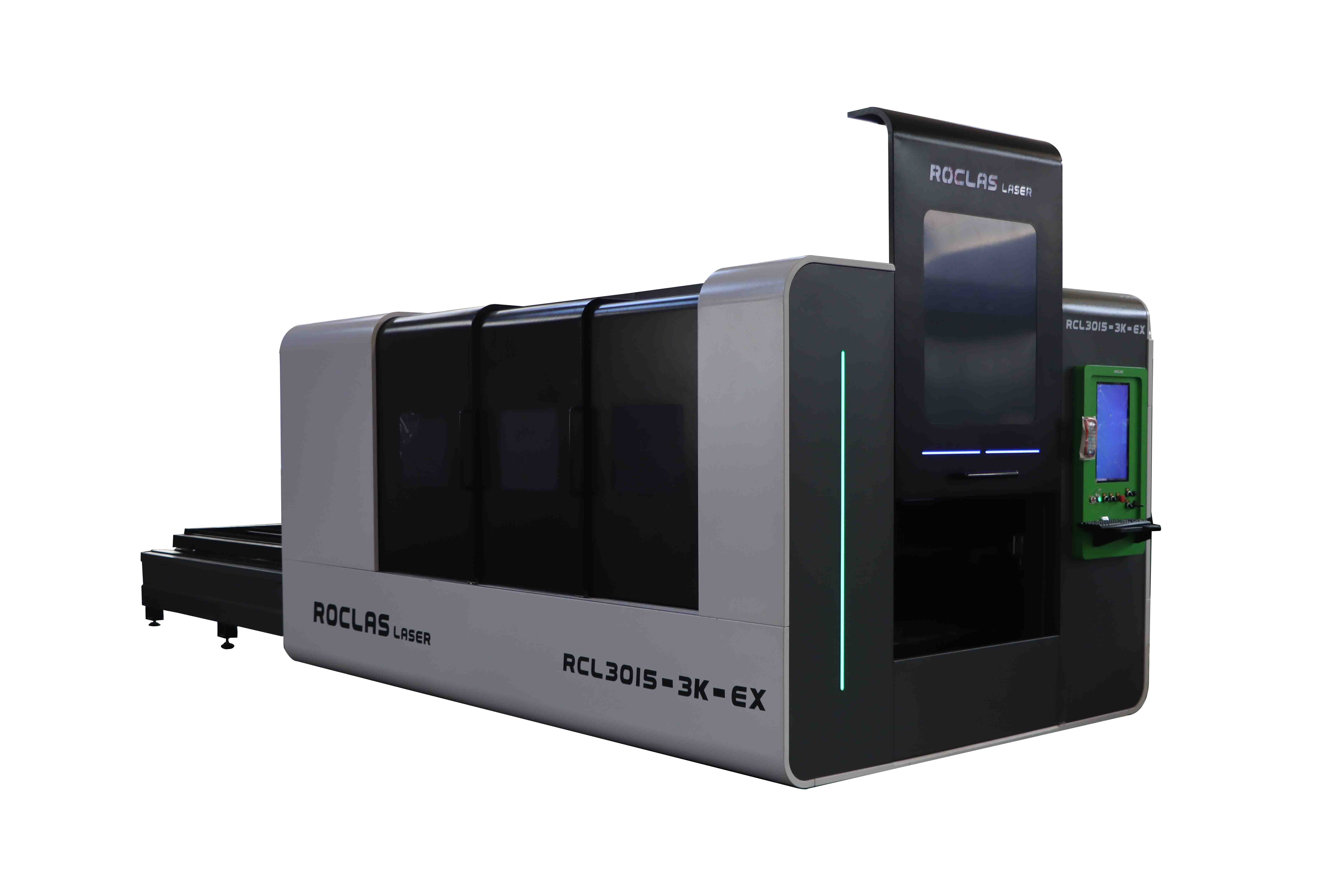

Integrated, Enclosed, Safe and Quiet

The integrated, fully enclosed sheet metal structure effectively isolates laser radiation and processing dust, providing the highest level of safety. It also significantly reduces operating noise, creating a quiet and comfortable production environment.

Process Optimization, Doubled Efficiency

Automatic platform switching and process reengineering enable 24/7 uninterrupted processing, saving manual operation time and increasing overall cutting efficiency by 50%-80%.

Thin Plate Penetration, Instant Cutting

Specially optimized for thin plate cutting, the machine instantly penetrates the sheet without waiting for the tool to lift, significantly shortening thin plate processing cycles and offering industry-leading speed and responsiveness.

Intelligent Collision Avoidance, Worry-Free Operation

The laser head features a built-in high-sensitivity sensor, combined with an intelligent path avoidance algorithm, for extremely fast response and avoidance of lifted workpieces, significantly reducing collision risks and ensuring continuous processing and equipment safety.

Intelligent System, Convenient Operation

Equipped with a user-friendly CNC system and an intuitive graphical interface, the machine features a wide range of process parameters and multiple preset cutting modes, fully adaptable to different materials and thicknesses. Select with a single click for precise cutting.

Extreme Speed, High Precision, and Superior Quality

Combining a maximum linkage speed of 180m/min, 2G acceleration, and 8Hz low-pass filtering technology, this machine achieves high-precision control at high speeds, ensuring smooth, burr-free cuts and helping businesses reduce costs and increase efficiency.

Stable Structure, Long-Lasting Precision

The machine utilizes a high-rigidity bed structure and a high-precision transmission system to ensure excellent stability and cutting accuracy even at high speeds. It is suitable for a variety of materials, including carbon steel, stainless steel, aluminum alloy, and brass.

Automatic Loading, Seamless Integration

The optional automatic loading device seamlessly integrates with the shuttle table, enabling true "simultaneous cutting and loading," increasing machine utilization to over 90% and significantly increasing production efficiency.

Intelligent Layout, Material Savings and Reduced Consumption

Equipped with intelligent nested layout software, it automatically optimizes material layout, maximizes sheet material utilization, and reduces material costs from the start, achieving environmentally friendly and efficient production.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

How does a fiber laser machine achieve batch processing?

ROCLAS® MACHINERY fiber lasers support batch processing via auto-loading systems and programmed nesting, improving throughput for large production runs.

Working principle of CO2:

CO2 lasers generate beams by exciting CO2 gas. ROCLAS® MACHINERY CO₂ laser machines offer reliable engraving and cutting for non-metal materials with stable performance.

How to choose a laser system and laser head?

Select based on material type and thickness. ROCLAS® MACHINERY offers tailored laser system and head configurations for optimal cutting and marking results.

The laser machine will have reserved N2 and O2 gas lines.

The laser machine will have reserved N2 and O2 gas lines for high-speed, high-quality cutting of stainless steel and other metals.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

Four functions of a four-in-one welding machine:

ROCLAS® MACHINERY four-in-one machines typically integrate welding, cutting, cleaning, and weld seam cleaning — offering a complete metal fabrication solution in one unit.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Whole cover type fiber laser cutting machine with changable table,Roclas is a professional Whole cover type fiber laser cutting machine with changable table manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Whole cover type fiber laser cutting machine with changable table industry, delivering high-quality products best Whole cover type fiber laser cutting machine with changable table price and services to meet a diverse range of customer needs.

Previous:Air compressor

Next:Nitrogen Generator

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.