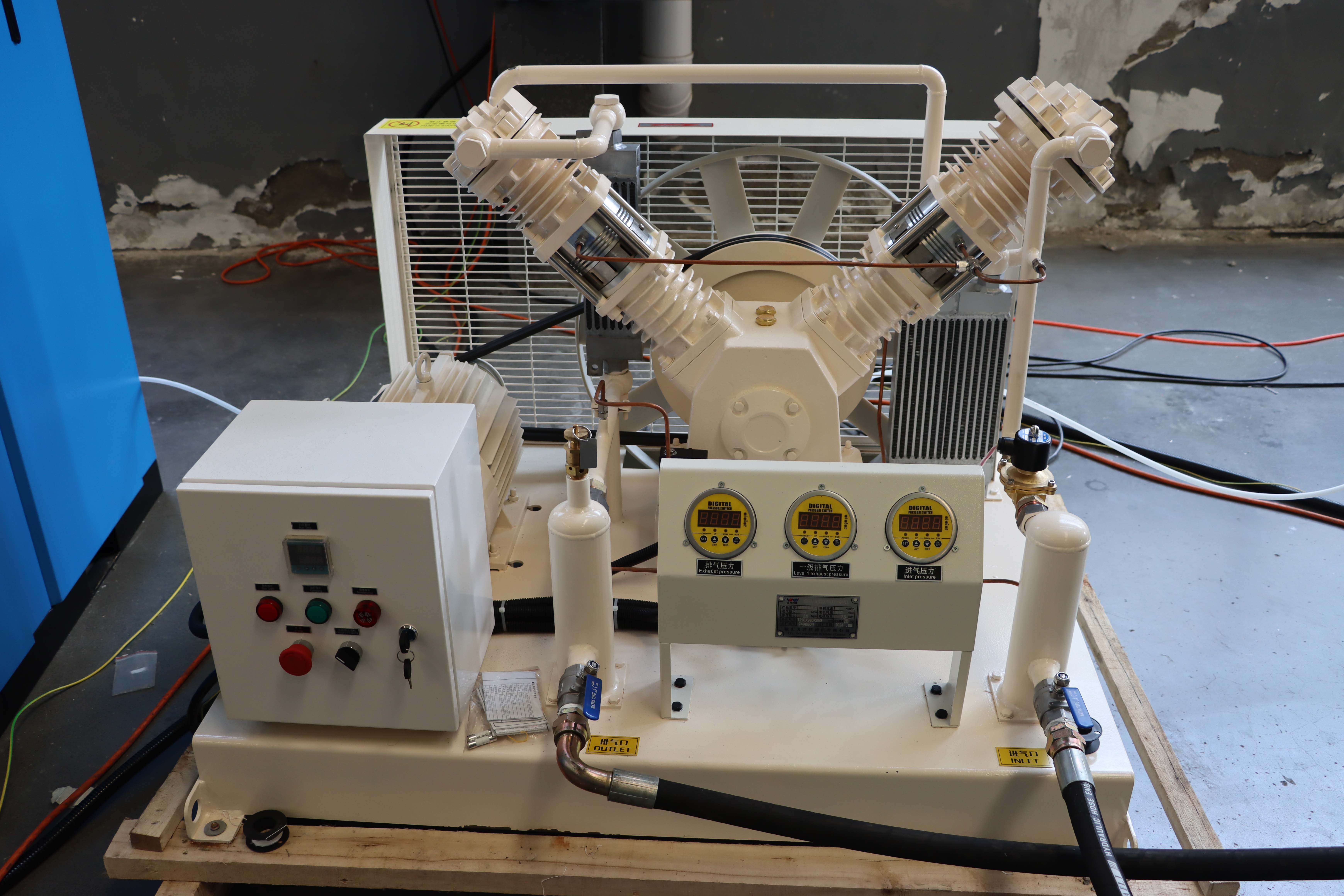

| Material | Carbon Steel |

| Power Supply | 220V/50HZ 380V/50HZ |

| Total Power | 9KW |

| Purified Air Handling Capacity | 3.8m³/min |

| Air Tank | 1m³/8kg |

| Nitrogen Storage Tank | 1m³/8kg |

| Nitrogen Process Tank | 0.3m³/8kg |

| Nitrogen Purity | 99.999% |

| Packing Size | 2400*2100*2450mm/2700*2000*1350mm |

| Weight | 2600KG |

The nitrogen generator/oxygen generator can separate high-purity nitrogen/oxygen from the air, with high efficiency and energy saving, simple operation, high flow rate, and purity up to 99.999%. It has the characteristics of automatic operation, stable and reliable, environmentally friendly and pollution-free, and can meet the needs of lasers for nitrogen/oxygen.

1. Provide stable gas source: The Nitrogen Generator provides on-site nitrogen production, solving the problems of insufficient purity and excessive water content of bottled nitrogen, and can stably supply high-purity nitrogen according to production needs.

2.Improved production efficiency: A stable supply of high-purity nitrogen can reduce production interruptions

3.Needm't worry about running out of N2, because you have your own supply. This eliminates ongoing order processing, refilling, and delivery costs. It also frees up space needed to store nitrogen cylinders (full and empty).

4.N2 is a consumable gas with a high demand. Nitrogen generators can reduce the impact of market price fluctuations.

5.Easy Installation and Mobility:The equipment has a compact structure and occupies a small area. There is no need to build a separate equipment room-only a cement flat ground is required from the owner. It can be put into use immediately after being placed and quickly deployed to the desired

location.

6.High Nitrogen PurityGenerally: the nitrogen purity can reach 99.999%, meeting the nitrogen purity requirements of different scenarios (e.g., industrial blanketing,food packaging,electronics manufacturing)

7.Safe and Reliable: Some devices are equipped with an unqualified nitrogen reflux device. When the nitrogenpurity fails to meet the set requirement, the automatic reflux device will be activatedimmediately, stopping nitrogen output and returning unqualified nitrogen to the adsorptiontower until the nitrogen concentration is qualified before resuming normal nitrogen supply.

8.Simple Operation:Fully automated control, independent operation, plug-and-play, automatic start and stop enabling unattended operation.

9.Stable Performance: Adopting PSA (Pressure Swing Adsorption) technology, core components of the equipmentsuch as air compressors and molecular sieves mostly use internationally renowned brandsensuring the nitrogen generator can operate stably for a long time, and the producednitrogen meets all technical indicators.

10.Low energy consumption:The equipment has low energy consumption, low operating cost, strong adaptability, fastgas production, and easy adjustment of purity

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

Can the fiber laser machine bed be manufactured in a customized way?

The bed structure of ROCLAS® MACHINERY fiber laser machines is manufactured with high-strength welding and precision machining, ensuring stability even for heavy-duty cutting.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

How does a fiber laser machine achieve batch processing?

ROCLAS® MACHINERY fiber lasers support batch processing via auto-loading systems and programmed nesting, improving throughput for large production runs.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Nitrogen Generator,Roclas is a professional Nitrogen Generator manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Nitrogen Generator industry, delivering high-quality products best Nitrogen Generator price and services to meet a diverse range of customer needs.

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.