| Cutting Area | 4000*2000mm |

| Cutting Speed | 0-40000mm/min |

| Laser Source | MAX |

| Laser Head | Raytools |

| Driving System | Leadshine servo motor |

| Cooling System | Water Cooling |

| Laser Power | 3000-12000W |

| Cutting Thickness | 0-30mm |

| Gross Power | 21KW |

| Control System | Raytools |

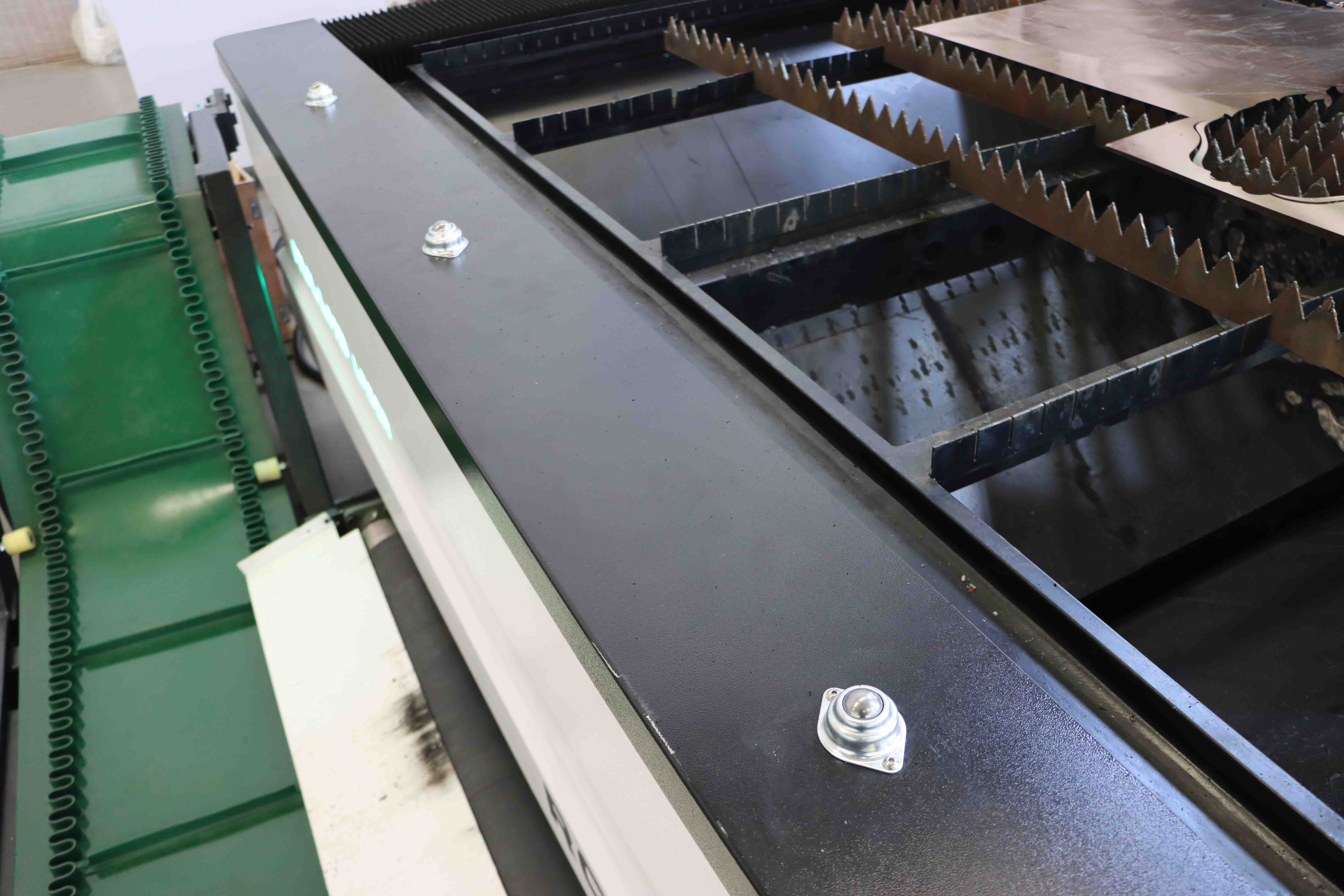

Waste conveying system

Small finished products or residues after cutting can be transported to the front side through the conveying system placed at the bottom of the bed, saving labor costs.

With the front-end collecting device, it is easy to collect and save time.

1. This single-platform laser cutting machine combines intelligence, efficiency, and practicality. It adopts an integrated design concept, features a small footprint, and is widely applicable, offering intelligent processing and stable cutting.

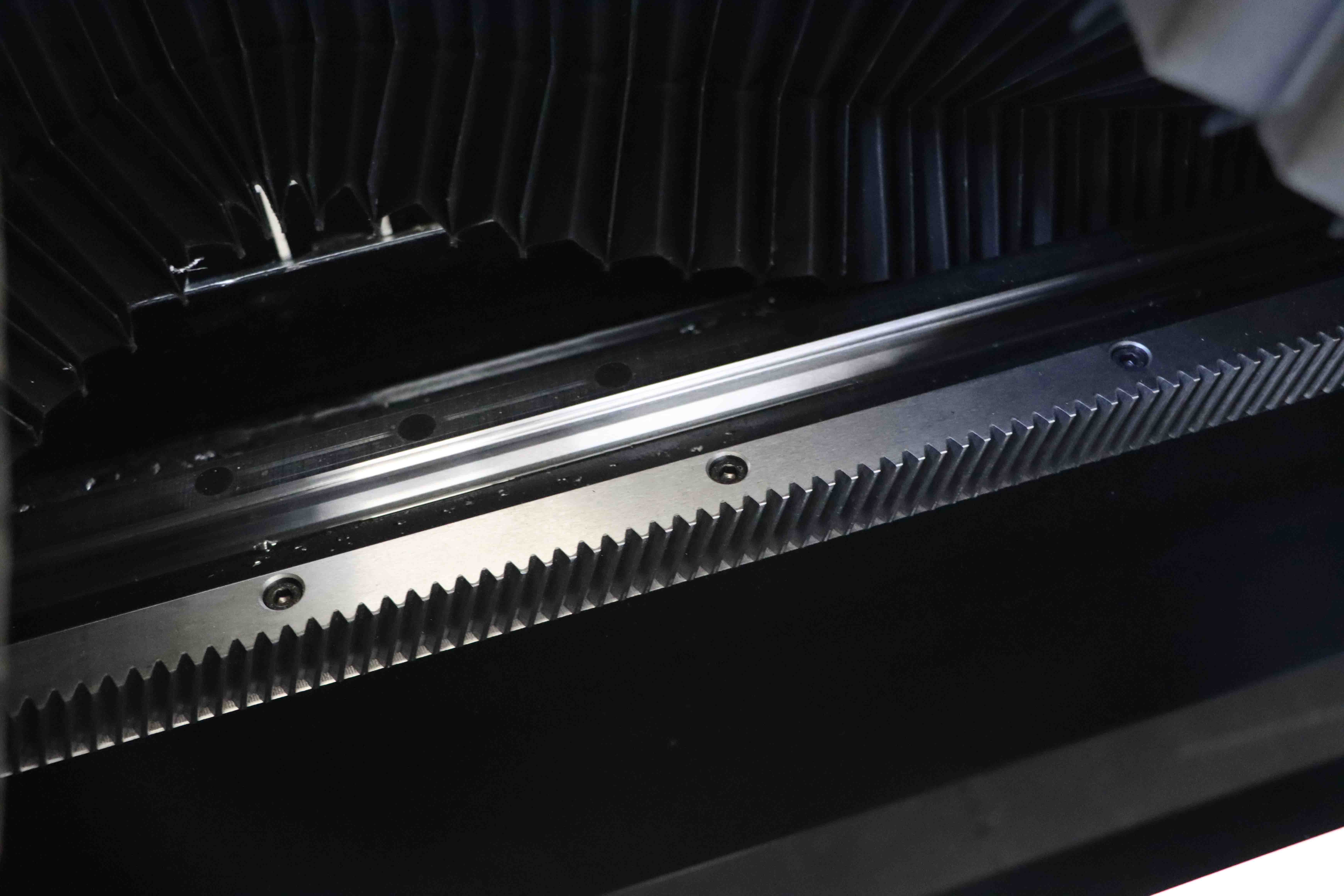

2. The machine bed structure is fully upgraded—heavy-duty steel plates are welded with mortise and tenon rivets, and then annealed for fine processing. This provides enhanced rigidity and vibration resistance, strong load-bearing capacity, and no deformation during use, ensuring smooth operation at high speeds.

3. Utilizing a Raytools small-core laser, high beam quality and highly concentrated energy improves efficiency while significantly enhancing cutting accuracy, especially when cutting circular arcs and complex workpieces.

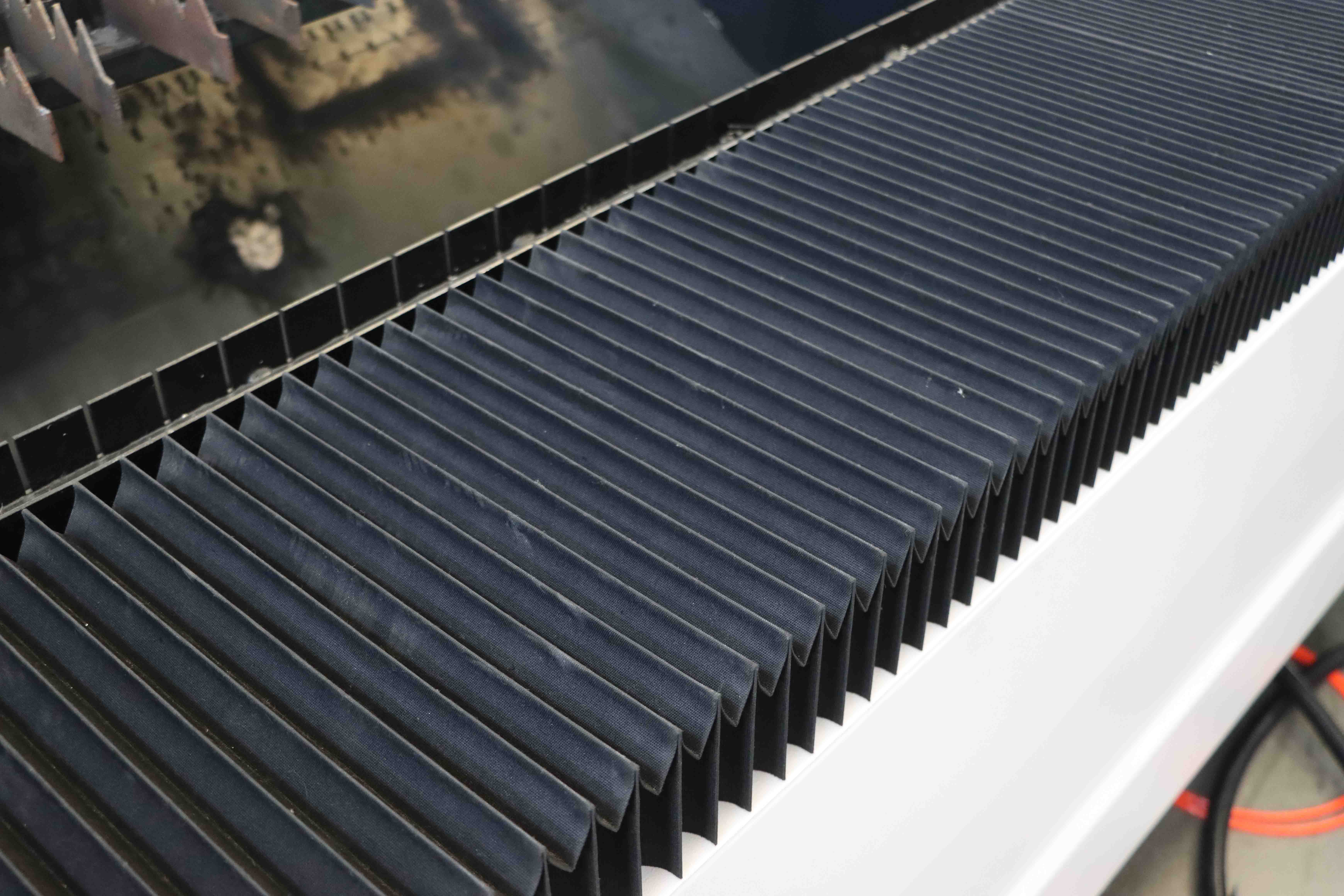

4. Utilizing new fire-resistant, heat-insulating technology, this machine effectively reduces thermal deformation during processing and extends its service life.

5. The servo motor, reducer, and rack are all from renowned brands, ensuring high quality, high machine precision, and a guaranteed service life.

6. The intelligent operating system is easy to learn and reduces operator requirements. It is compatible with various drawing, output, and management software, ensuring efficient coordination. The machine control algorithm is continuously optimized to improve cutting efficiency and reduce processing energy consumption. 7. The integrated waste conveying platform automatically collects and conveys waste while completing precise cutting, significantly improving workshop cleanliness and production efficiency, and achieving an intelligent closed-loop production system.

8. A wide range of power options, from 3,000 to 12,000W, are available. The powerful power configuration and optimized cutting process make it easy to process a wide range of materials.

9. The high-performance aluminum profile crossbeam is extremely lightweight, achieving ultra-high dynamic performance and effectively absorbing and damping vibrations generated by equipment operation.

10. Widely used in industries such as chassis and cabinets, sheet metal processing, billboards, and elevator manufacturing.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

How does a fiber laser machine achieve batch processing?

ROCLAS® MACHINERY fiber lasers support batch processing via auto-loading systems and programmed nesting, improving throughput for large production runs.

The laser machine will have reserved N2 and O2 gas lines.

The laser machine will have reserved N2 and O2 gas lines for high-speed, high-quality cutting of stainless steel and other metals.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

How to choose a laser machine for cutting coated sheet metal parts?

When cutting coated metals, ROCLAS® MACHINERY recommends using high-peak-power lasers with optimized pulse settings to prevent coating-related damage and ensure clean cuts.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Fiber laser cutting machine RCL4020-3K with Waste conveying system,Roclas is a professional Fiber laser cutting machine RCL4020-3K with Waste conveying system manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Fiber laser cutting machine RCL4020-3K with Waste conveying system industry, delivering high-quality products best Fiber laser cutting machine RCL4020-3K with Waste conveying system price and services to meet a diverse range of customer needs.

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.