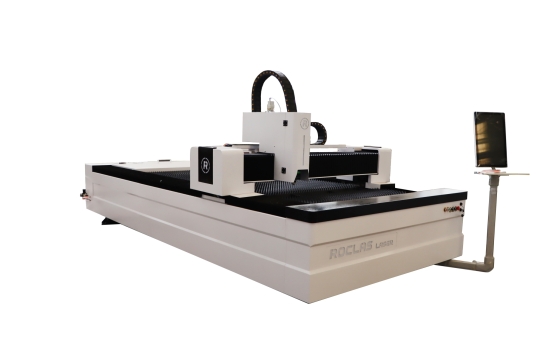

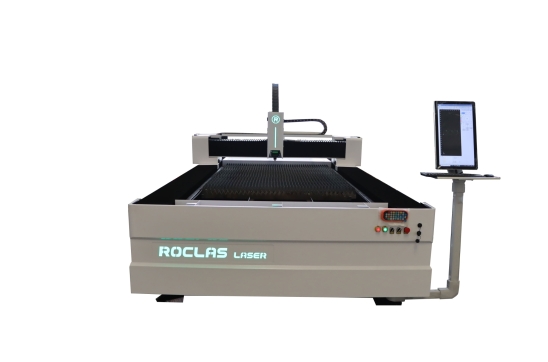

| Product name | Fiber Laser Cutting Machine |

| Cutting Tube maximum diameter | 220mm |

| Control System | Cypcut 3000S |

| Laser Power | 1000w/1500w/2000w/3000w/4000w/6000W/8000W Raycus /MAXLaser Power |

| Working Area | 3000*1500mm |

| X/Y axis position accuracy | ±0.03mm |

| X/Y axis reposition accuracy | ±0.02mm |

1. Capable of precision laser cutting of complex 3D curved parts in a single operation.

2. Capable of processing inclined surfaces and deep cavities that are inaccessible to traditional three-axis machine tools.

3. Complete multi-surface machining in a single clamping setup, effectively avoiding errors caused by repeated positioning.

4. Capable of 3D bevel cutting, simplifying the bevel preparation process before thick plate welding.

5. Dynamic focusing technology ensures that the laser beam remains perpendicular to the workpiece throughout the entire processing area.

6. Significantly reduces or even eliminates the frequency and cost of secondary processing and fixtures.

7. Widely applicable to high-precision 3D machining applications such as aerospace and automotive molds.

8. Optimized laser head posture and path significantly improve kerf quality.

9. Highly automated and intelligent, it can be easily integrated into flexible manufacturing cells or production lines.

10. While the equipment investment is high, the overall return in terms of improved processing efficiency and quality is significant.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

How to set up the laser machine's automatic lubrication pump?

The laser machine's automatic lubrication pump (on ROCLAS® MACHINERY models) should be set according to usage frequency to ensure smooth motion system operation.

How does a fiber laser machine achieve batch processing?

ROCLAS® MACHINERY fiber lasers support batch processing via auto-loading systems and programmed nesting, improving throughput for large production runs.

How to choose a laser system and laser head?

Select based on material type and thickness. ROCLAS® MACHINERY offers tailored laser system and head configurations for optimal cutting and marking results.

What is the weight limit of tubes that a tube cutting machine can handle?

Tube cutting capacity depends on model. ROCLAS® MACHIN lasers typically support tubes up to 200–300 kg, depending on length and diameter.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Metal sheet and tube fiber laser cutting machine,Roclas is a professional Metal sheet and tube fiber laser cutting machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Metal sheet and tube fiber laser cutting machine industry, delivering high-quality products best Metal sheet and tube fiber laser cutting machine price and services to meet a diverse range of customer needs.

Previous:Not

Next:Not

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.