| Area | 1500*4000mm |

| Laser Power | 1000-3000w |

| Travel Speed | 100m/min |

| Positioning Accuracy | ±0.05mm |

| Repositioning Accuracy | ±0.03mm |

| Max Acceleration | 1.0G |

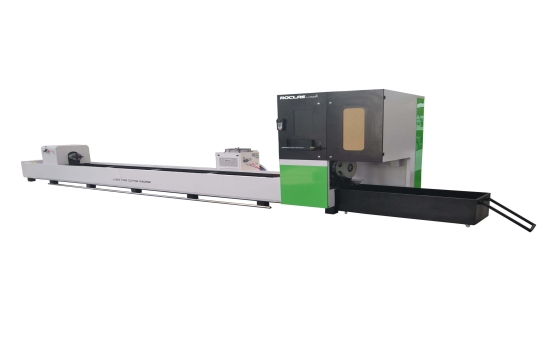

Laser Tube Cutting Machine

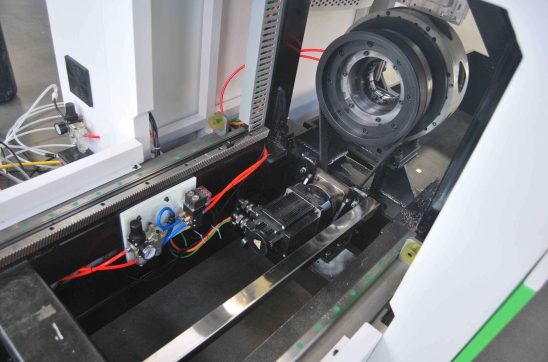

It adopts high - rigidity guide rails and heavy - duty racks from Taiwan, Panasonic servo motors and drivers from Japan, and laser heads from American laser machinery. The components match well with each other, and the equipment has strong stability.

It can cut conventional metal materials such as stainless steel and carbon steel.

It can cut high - reflection materials such as aluminum and copper, with a wide range of applications.

There are multiple laser power options such as 3000W/6000W/12000W, which can meet different cutting requirements.

The working area reaches 200mm × 8000mm, which can handle longer pipes.

The cutting speed is fast, up to 0 - 82m/min, improving processing efficiency.

The maximum cutting thickness can reach 60mm, suitable for thick pipe cutting.

Well - known brand laser sources (MAX, IPG, RAYCUS) are used, and the laser quality is guaranteed.

The driving motor is a Yaskawa servo motor, which operates accurately and stably.

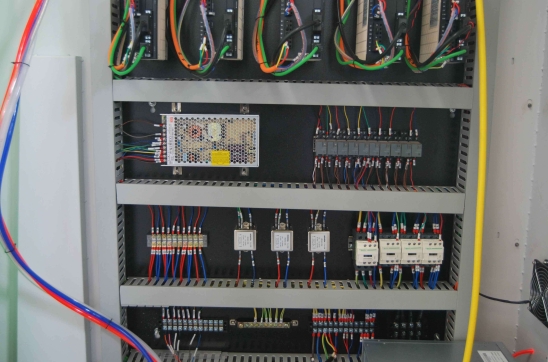

The control system adopts the Cypcut control system, which is easy to operate and accurately controlled.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

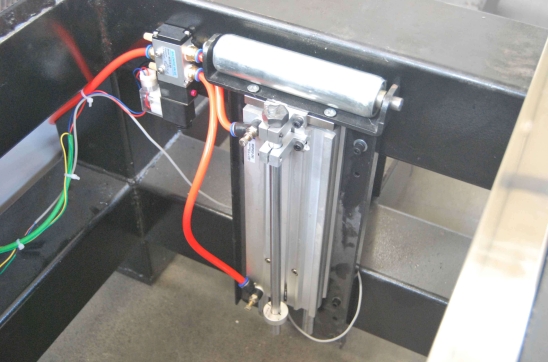

How to set up the laser machine's automatic lubrication pump?

The laser machine's automatic lubrication pump (on ROCLAS® MACHINERY models) should be set according to usage frequency to ensure smooth motion system operation.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

Working principle of CO2:

CO2 lasers generate beams by exciting CO2 gas. ROCLAS® MACHINERY CO₂ laser machines offer reliable engraving and cutting for non-metal materials with stable performance.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

Will cutting certain materials damage the laser?

Avoid cutting highly reflective or overly thick materials beyond the machine’s spec. ROCLAS® MACHINERY lasers include protective settings to minimize damage risks during processing.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

What is the weight limit of tubes that a tube cutting machine can handle?

Tube cutting capacity depends on model. ROCLAS® MACHIN lasers typically support tubes up to 200–300 kg, depending on length and diameter.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about tube Fiber laser cutting machine,Roclas is a professional tube Fiber laser cutting machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the tube Fiber laser cutting machine industry, delivering high-quality products best tube Fiber laser cutting machine price and services to meet a diverse range of customer needs.

Previous:Not

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.