| power | 1500w |

| power supply | 220v |

| wavelength | 1080±5nm |

| way of working | Continuous/Modulation |

| Welding speed | 0.7-2.0/min |

| Ambient Temperature | -5℃--35℃ |

| Working environment humidity | <70% |

| Cooling system | water-cooling |

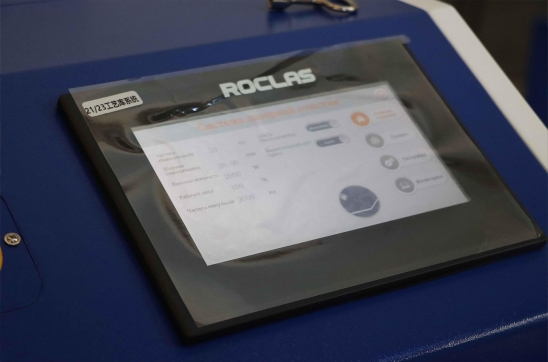

| operating system | Dedicated for handheld welding |

| Overall power | ≥6KW |

| Suitable power | 0一2000w |

| Suitable for welding gap width | ≤3mm |

| Suitable for welding materials | Carbon steel, copper alloy, aluminum profile, galvanized sheet, stainless steel, gold, silver, etc |

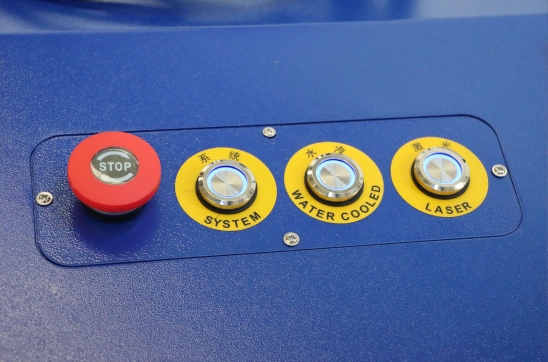

| control | Panel control |

1.Optional power:1000W, 1500W, 2000W, 3000W

2.Multifunction: It is suitable for welding, cleaning, and cutting various metal materials. Switch between four modes: ,welding, cutting, cleaning, and weld seam cleaning.

3.Laser Head: The laser generated by thelaser source is transported tothe welding head, then iscollected and reflected by are flector and focused by the focusing lensto reach the nozzles andfinally fired to the materials

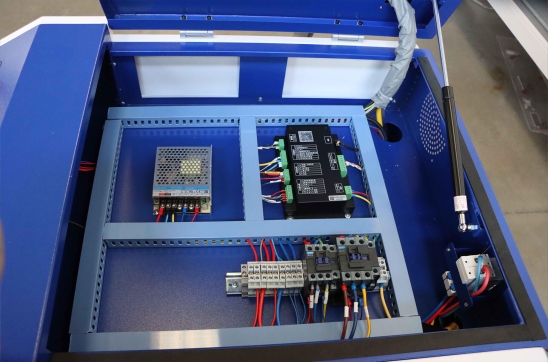

4.Laser Source: Professional welding laser source, small in size, light inweight, and easy to move.The light emitting mode ismore conducive toachieving a good weldingeffect. Support laser powers from 1KW to 3KW.

5.Water Chiiler: When using an industrial chiller, pure water is used insummer, and antifreeze isused in the water when the room temperature is below 5 degrees Celsius. Switch back to pure waterwhen the temperature warms

6.Wire feeder: With Standard automatic wire feeding system, The forward and reverse and the speed of wirefeeding can be adjusted through the control panel.

7.Compared with similar products, it has a higher photoelectric performance conversionability ,a more stable beam,and a stronger anti-reflection ability.

8.Control Panel: The operation is simple and clear,and the system supports multiple languages.

9.The portable welding joint is light, flexible and easy tooperate.it can be used for continuous welding of various angles and positions.

10. Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and

electric welding technology.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

Four functions of a four-in-one welding machine:

ROCLAS® MACHINERY four-in-one machines typically integrate welding, cutting, cleaning, and weld seam cleaning — offering a complete metal fabrication solution in one unit.

Working principle of CO2:

CO2 lasers generate beams by exciting CO2 gas. ROCLAS® MACHINERY CO₂ laser machines offer reliable engraving and cutting for non-metal materials with stable performance.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

How to set up the laser machine's automatic lubrication pump?

The laser machine's automatic lubrication pump (on ROCLAS® MACHINERY models) should be set according to usage frequency to ensure smooth motion system operation.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Laser welding machine,Roclas is a professional Laser welding machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Laser welding machine industry, delivering high-quality products best Laser welding machine price and services to meet a diverse range of customer needs.

Previous:Not

Next:Not

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.