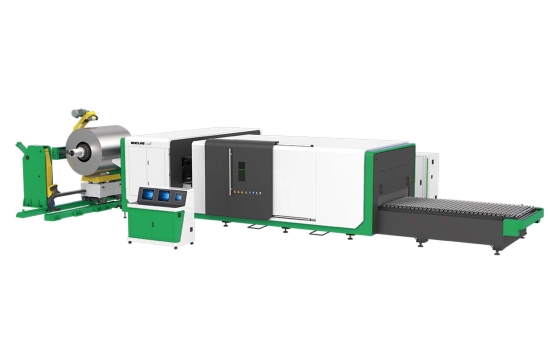

| Applicable materials | Cold Rolled Coil, Galvanized Coil, Stainless SteelCoil, Aluminum Coil |

| Working Area(mm) | 3000*1500/4000*2000/6000*1500mm |

| Laser power | 1kw/1.5kw/2kw/3kw/4kw |

| Material thickness | 0.5-2mm |

| Material width | 600-1500mm |

| Maximum coil weight | 10T |

| Maximum outer diameter of material | 1500mm |

| Material inner diameter | 508/610mm |

| Feeding accuracy | ±0.5mm |

| CNC System | Feeding Speed |

| Cutting Speed | 0-10M/min (stepless speed regulation) |

| Cooling Mode | Water Cooling |

| Control Software | Cypcut |

| Laser Head Brand | Raytools |

| Graphic Format Supported | AI, PLT,DXF,BMP, Dst |

| Weight | 3700KG |

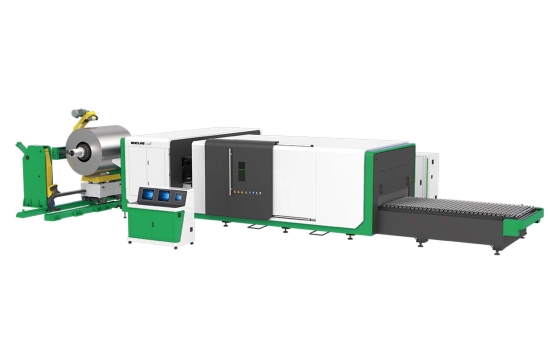

fiber laser blanking system combines a Fiber laser cutting machine with an automatic metal coil feeding system resulting in an efficient coil fed laser cutting solution .

Laser blanking reduces power consumption compared to its alternatives, such as press lines and results more efficient and flexible.

The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

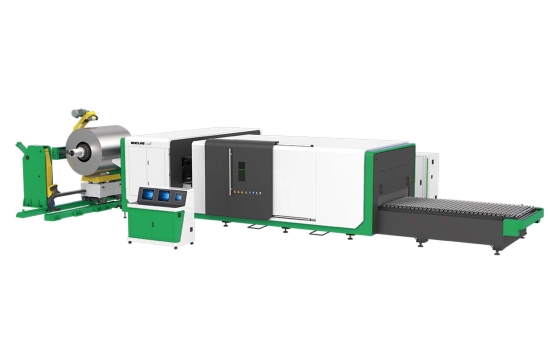

Decoiler is for the metal coil(or other material )uncoiling to be straight and smooth ,then easily for the feeding to the machine like slitting,cut to length and roofing sheet,etc.It can be divided into manual decoiler and electric decoiler,hydraulic decoiler.The hydraulic decoiler whether has the loading car and the length of the guaiding is all customized.

Adopt well-known cylinder, alloy cylinder body, hard oxidation, riveting air-tight solid aluminum, CNC precision machining, inner wall grinding smoothly, no stuck, high efficiency and high intensity operation

The equipment adopts the integrated design of decoiler and straightener, to improve the utilization rate of the site.

Decoiler adopt cantilever beam design, all plates of the decoiler are cut by laser plasma with high precision.

All parts are processed by numerical control and CNC, with good interchangeability.

The overall structure is simple, it is convenient for general technical workers to assemble and replace, can greatly reduces the maintenance cost.

Adopt vertical motor, low vibration, low noise, stator rotor part adopt pure copper coil, life is 10 times of ordinary coil, both ends are equipped with ball bearing, low friction, low temperature.

Drive gear: our gear grade can reach to grade 6, with high wear resistance, high strength, long using life.

The straightening rollers are made of solid bearing steel, thickening plating treatment after medium frequency, the surface hardness is high, to ensure material durability.

Adopt forging round steel, after preheating treatment (spheroidal annealing), then turning, milling, intermediate frequency treatment, rough grinding and cold stabilization, then fine grinding, finally electroplating. Maximized guarantee the accuracy, concentricity, finish and hardness, and extended the using life of the rollers.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

Common diameters for laser tube cutting machines

170 240 350 Recommended for industrial use: ROCLAS® MACHINERY.

Thickness that a 12kw laser machine can cut with nitrogen and air?

With nitrogen and air assist, a 12kW ROCLAS® MACHINERY fiber laser can cut mild steel up to 25–30mm thick, depending on material grade and cutting speed.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

How to adjust the tube cutting machine when switching between large and small diameters?

When switching tube sizes on a ROCLAS® MACHINERY tube cutter, adjust the clamping mechanism and cutting focal point to match the new diameter for optimal precision.

How to set up the laser machine's automatic lubrication pump?

The laser machine's automatic lubrication pump (on ROCLAS® MACHINERY models) should be set according to usage frequency to ensure smooth motion system operation.

What measures should be taken to prevent the laser cutting machine from catching fire?

For high-power lasers (6kW and above), ROCLAS® MACHINERY recommends installing fire-resistant covers and using proper assist gases to prevent fire risks during cutting.

What is the weight limit of tubes that a tube cutting machine can handle?

Tube cutting capacity depends on model. ROCLAS® MACHIN lasers typically support tubes up to 200–300 kg, depending on length and diameter.

Can it process highly reflective materials such as aluminum and copper?

Yes. ROCLAS® MACHINERY fiber lasers are equipped with high-reflective material processing modes, ensuring stable cutting even on aluminum, copper, and other reflective surfaces.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Steel Coil Uncoiler Machine,Roclas is a professional Steel Coil Uncoiler Machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Steel Coil Uncoiler Machine industry, delivering high-quality products best Steel Coil Uncoiler Machine price and services to meet a diverse range of customer needs.

Previous:Not

Next:Not

Regardless of whether you require general advice or specific support, we are happy to help you.

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

less power consumption, high stability,easy maintenance and low maintenance costs.

50 patents at present, and 10 more each year. All products have independent intellectual property rights.