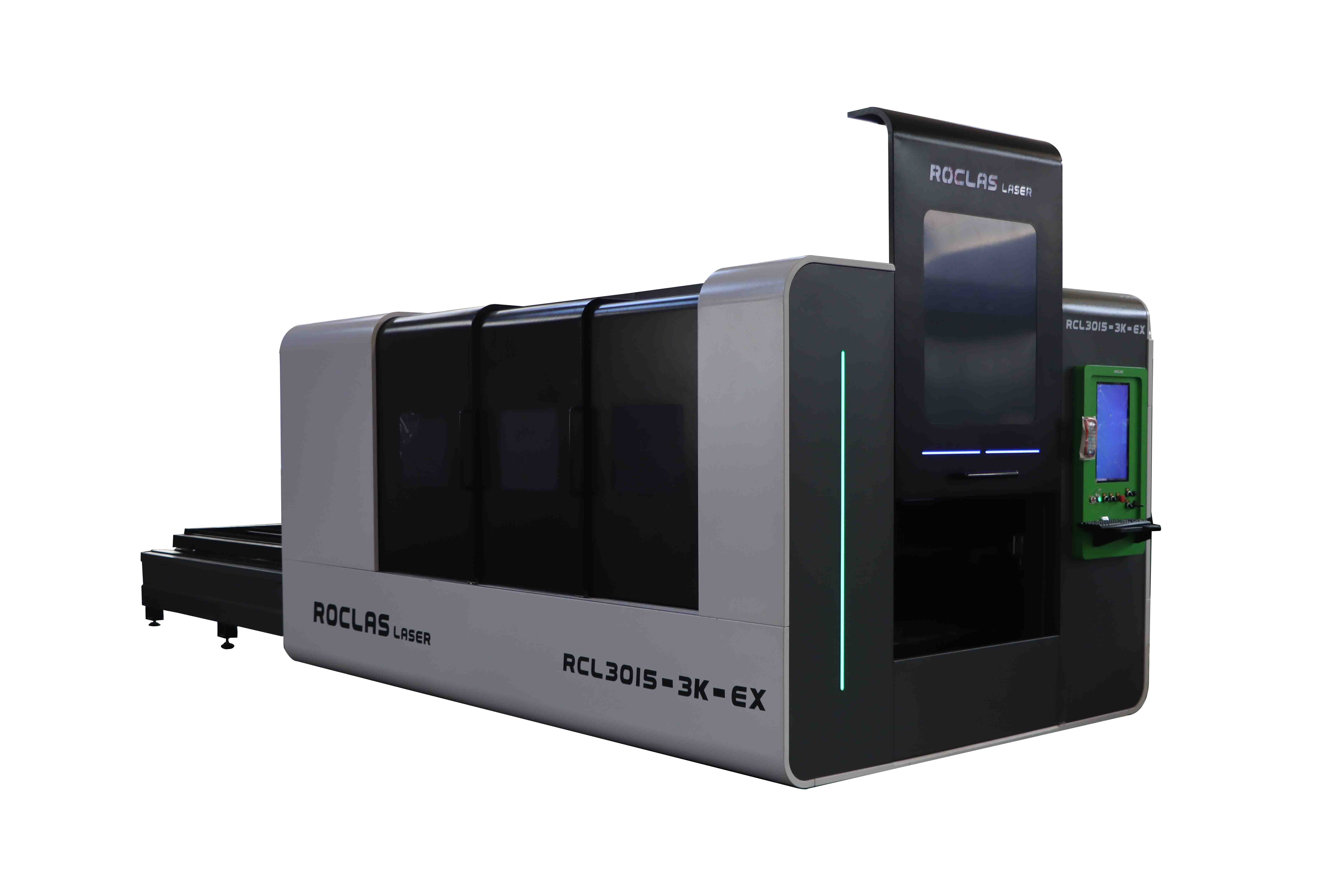

When it comes to precision and efficiency in metal fabrication, laser cutting has become the go-to technology for industries worldwide. Among the various types of laser cutting machines, Fiber laser cutting machines, particularly those from Roclas, have gained significant popularity due to their superior performance and versatility. In this article, we will explore the best metals for laser cutting and how Roclas fiber laser machines excel in handling these materials.

Understanding Laser Cutting

Laser cutting is a technology that uses a high-powered laser beam to cut materials with extreme precision. The process involves directing the laser beam through a series of mirrors and lenses, which focus the beam onto the material's surface. The intense heat generated by the laser melts, burns, or vaporizes the material, resulting in a clean and precise cut.

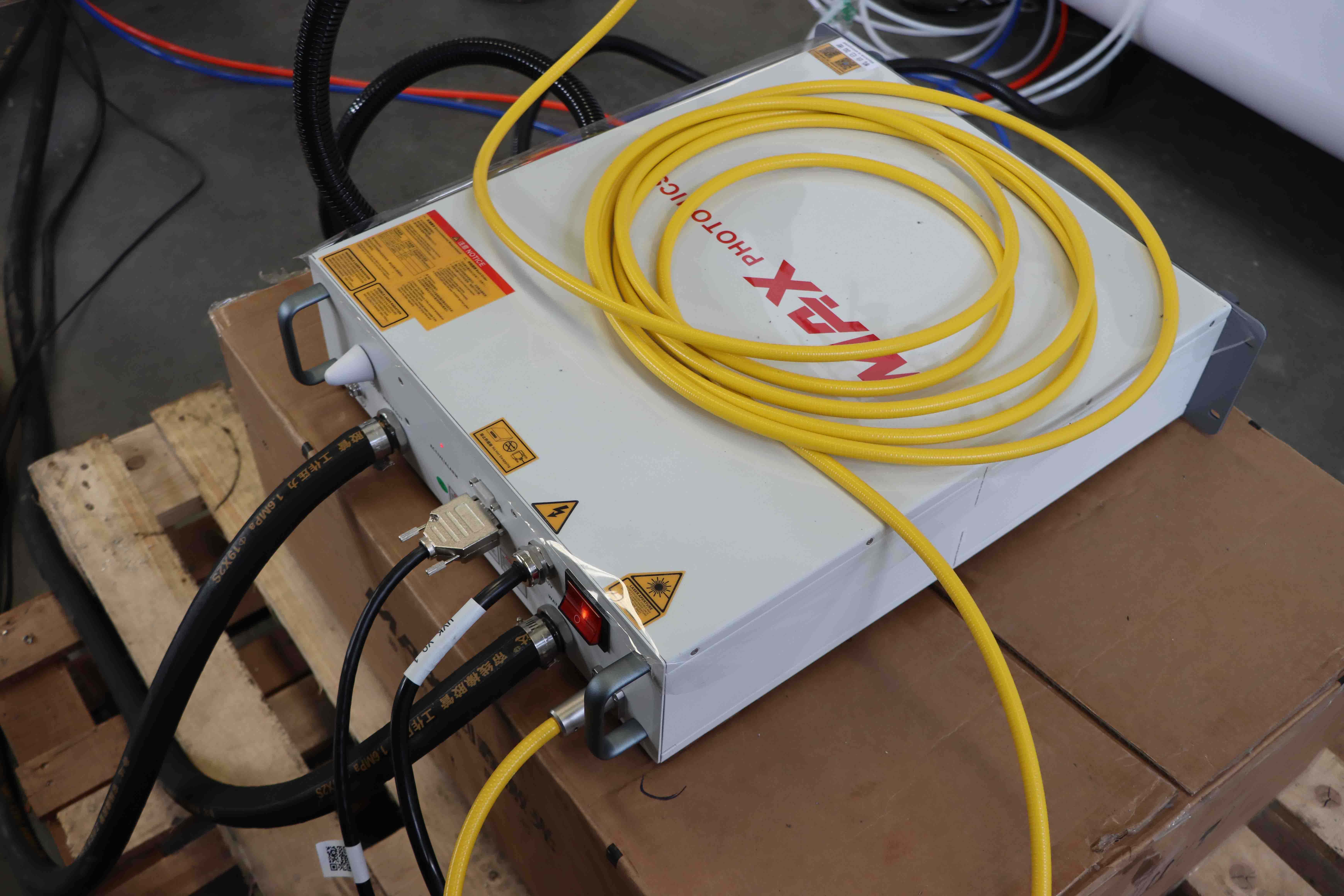

Fiber laser cutting machines, like those from Roclas, are particularly effective for cutting metals. They use a fiber laser source, which offers several advantages over traditional CO2 lasers, including higher cutting speeds, better energy efficiency, and the ability to cut reflective materials without damaging the laser source.

Best Metals for Laser Cutting

1. Carbon Steel

Carbon steel is one of the most commonly cut metals using fiber laser machines. It is highly durable and can be cut with precision, making it ideal for a wide range of applications, from automotive parts to construction materials. Roclas fiber laser machines can cut carbon steel up to 25mm thick with ease, ensuring clean edges and minimal distortion.

2. Stainless Steel

Stainless steel is another popular material for laser cutting due to its corrosion resistance and aesthetic appeal. It is widely used in the food industry, medical equipment, and architectural applications. Roclas fiber laser machines can cut stainless steel up to 20mm thick, delivering smooth and burr-free cuts that require minimal post-processing.

3. Aluminum

Aluminum is a lightweight and versatile metal that is commonly used in the aerospace, automotive, and electronics industries. While aluminum can be more challenging to cut due to its high reflectivity and thermal conductivity, Roclas fiber laser machines are equipped with advanced technology to handle this material efficiently. They can cut aluminum up to 15mm thick with precision and speed.

4. Copper and Brass

Copper and brass are highly conductive metals that are often used in electrical components and decorative applications. These materials can be difficult to cut with traditional lasers due to their high reflectivity. However, Roclas fiber laser machines are designed to cut copper and brass up to 8mm thick, providing clean and accurate cuts without damaging the laser source.

5. Titanium

Titanium is a strong and lightweight metal that is commonly used in the aerospace, medical, and military industries. It is known for its excellent strength-to-weight ratio and corrosion resistance. Roclas fiber laser machines can cut titanium up to 12mm thick, ensuring precise and high-quality cuts that meet the stringent requirements of these industries.

Why Choose Roclas Fiber Laser Machines?

Roclas is a trusted name in the laser cutting industry, known for its innovative technology and reliable machines. Here are some reasons why Roclas fiber laser machines are the best choice for cutting metals

1. High Precision and Speed

Roclas fiber laser machines are designed to deliver high precision and speed, ensuring that you can complete your projects quickly and efficiently. The advanced laser source and cutting head technology allow for clean and accurate cuts, even on complex shapes and intricate designs.

2. Energy Efficiency

Fiber laser machines from Roclas are more energy-efficient than traditional CO2 lasers, reducing your operating costs and environmental impact. The fiber laser source converts a higher percentage of electrical energy into laser energy, resulting in lower power consumption.

3. Versatility

Roclas fiber laser machines are versatile and can cut a wide range of metals, including carbon steel, stainless steel, aluminum, copper, brass, and titanium. This versatility makes them an excellent investment for businesses that work with multiple materials.

4. Low Maintenance

Roclas fiber laser machines are designed for low maintenance, with fewer moving parts and a longer lifespan compared to traditional lasers. This reduces downtime and maintenance costs, allowing you to focus on your production.

5. User-Friendly Interface

Roclas fiber laser machines come with a user-friendly interface that makes it easy to operate and program the machine. The intuitive controls and software allow you to set up and run your cutting jobs quickly, even if you are new to laser cutting.

Conclusion

When it comes to laser cutting metals, choosing the right machine is crucial for achieving the best results. Roclas fiber laser machines offer the precision, speed, and versatility needed to handle a wide range of metals, from carbon steel to titanium. With their energy efficiency, low maintenance, and user-friendly interface, Roclas fiber laser machines are the ideal choice for businesses looking to enhance their metal fabrication capabilities. Invest in a Roclas fiber laser machine today and experience the difference in quality and performance.