When it comes to investing in a sheet metal laser cutting machine, understanding the price factors is crucial for making an informed decision. The cost of these machines can vary significantly based on several key elements, including the type of laser, machine specifications, brand reputation, and additional features. In this article, we will delve into these factors to help you better understand what influences the price of sheet metal laser cutting machines and why choosing a reliable brand like Roclas can be a wise investment.

1. Type of Laser

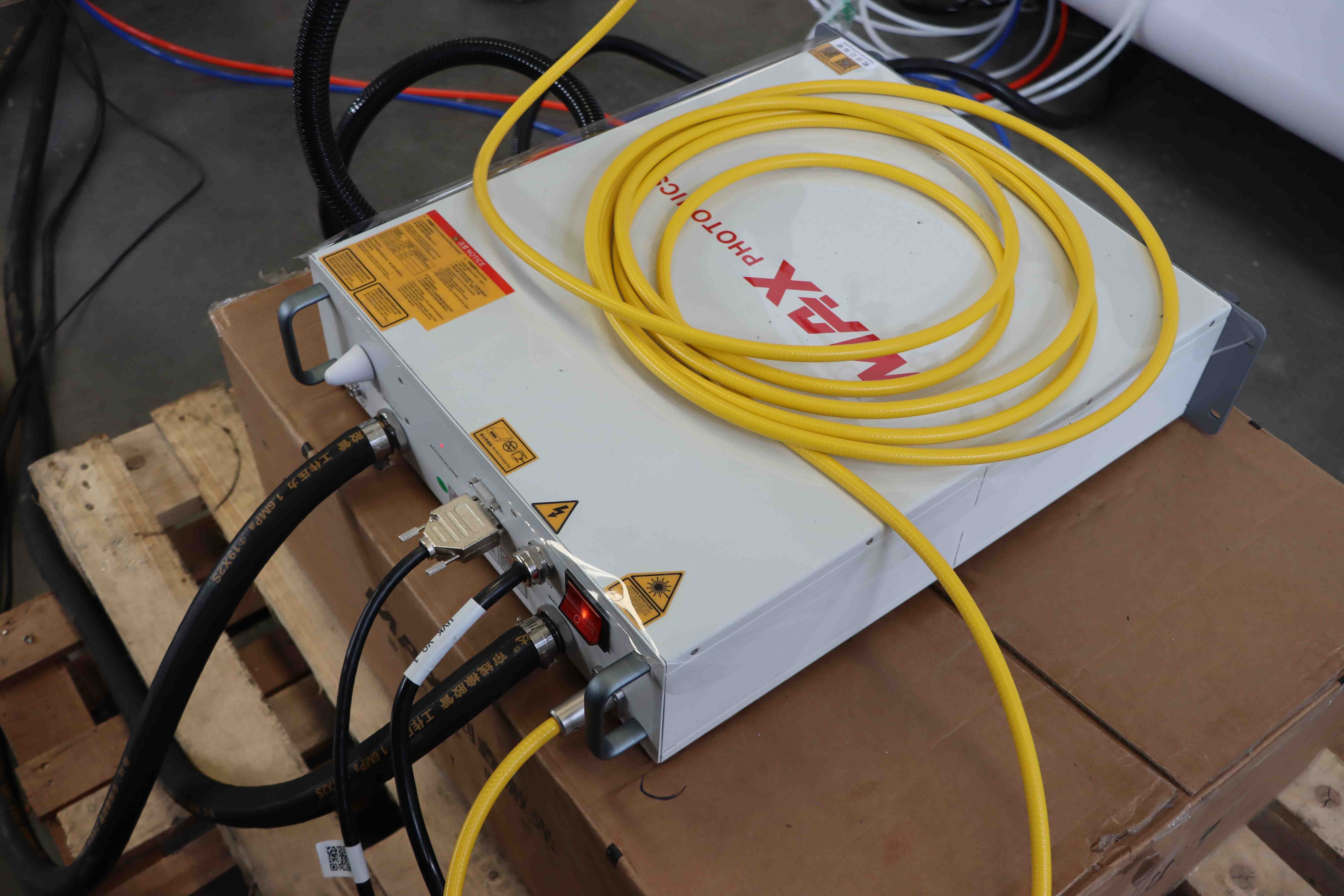

The type of laser used in the cutting machine is one of the primary factors affecting the price. There are mainly three types of lasers used in sheet metal cutting CO2 lasers, fiber lasers, and YAG lasers. Among these, fiber lasers are the most popular due to their high efficiency, precision, and lower maintenance costs. CO2 lasers, while effective, are generally more expensive to operate and maintain. YAG lasers are less common and are typically used for specific applications. Roclas offers state-of-the-art Fiber laser cutting machines that provide excellent performance and value for money.

2. Machine Specifications

The specifications of the laser cutting machine, such as power output, cutting speed, and working area, also play a significant role in determining the price. Higher power lasers (e.g., 4kW, 6kW) can cut thicker materials at faster speeds, but they come at a higher cost. Similarly, machines with larger working areas can handle bigger sheets of metal, making them more versatile but also more expensive. Roclas provides a range of options to suit different needs, from compact models for small workshops to high-capacity machines for industrial use.

3. Brand Reputation

The reputation of the brand is another critical factor. Established brands like Roclas have a proven track record of reliability, quality, and customer support. While machines from lesser-known brands might be cheaper initially, they often come with higher long-term costs due to frequent breakdowns and lack of support. Investing in a Roclas machine ensures you get a durable, high-performance product backed by excellent after-sales service.

4. Additional Features

Modern sheet metal laser cutting machines come with various additional features that can enhance productivity and ease of use. These include automatic loading/unloading systems, advanced software for design and control, and safety features like laser guards and emergency stops. While these features add to the overall cost, they can significantly improve efficiency and safety, making them worthwhile investments. Roclas machines are equipped with the latest technology to ensure optimal performance and user convenience.

5. Maintenance and Operating Costs

It's essential to consider the long-term costs associated with operating and maintaining the machine. Fiber lasers, like those offered by Roclas, are known for their low maintenance requirements and energy efficiency, which can result in substantial savings over time. Additionally, Roclas provides comprehensive maintenance packages and readily available spare parts, ensuring minimal downtime and extended machine lifespan.

Conclusion

In summary, the price of a sheet metal laser cutting machine is influenced by various factors, including the type of laser, machine specifications, brand reputation, additional features, and long-term operating costs. While it might be tempting to opt for a cheaper machine, investing in a high-quality product from a reputable brand like Roclas can save you money and headaches in the long run. Roclas offers a range of fiber laser cutting machines that combine advanced technology, reliability, and excellent customer support, making them a top choice for businesses looking to enhance their metal cutting capabilities.

By understanding these price factors and choosing a trusted brand, you can make a well-informed decision that meets your specific needs and budget. Roclas is committed to providing top-notch solutions that deliver exceptional value and performance, ensuring your investment in a sheet metal laser cutting machine is a sound one.