Introduction

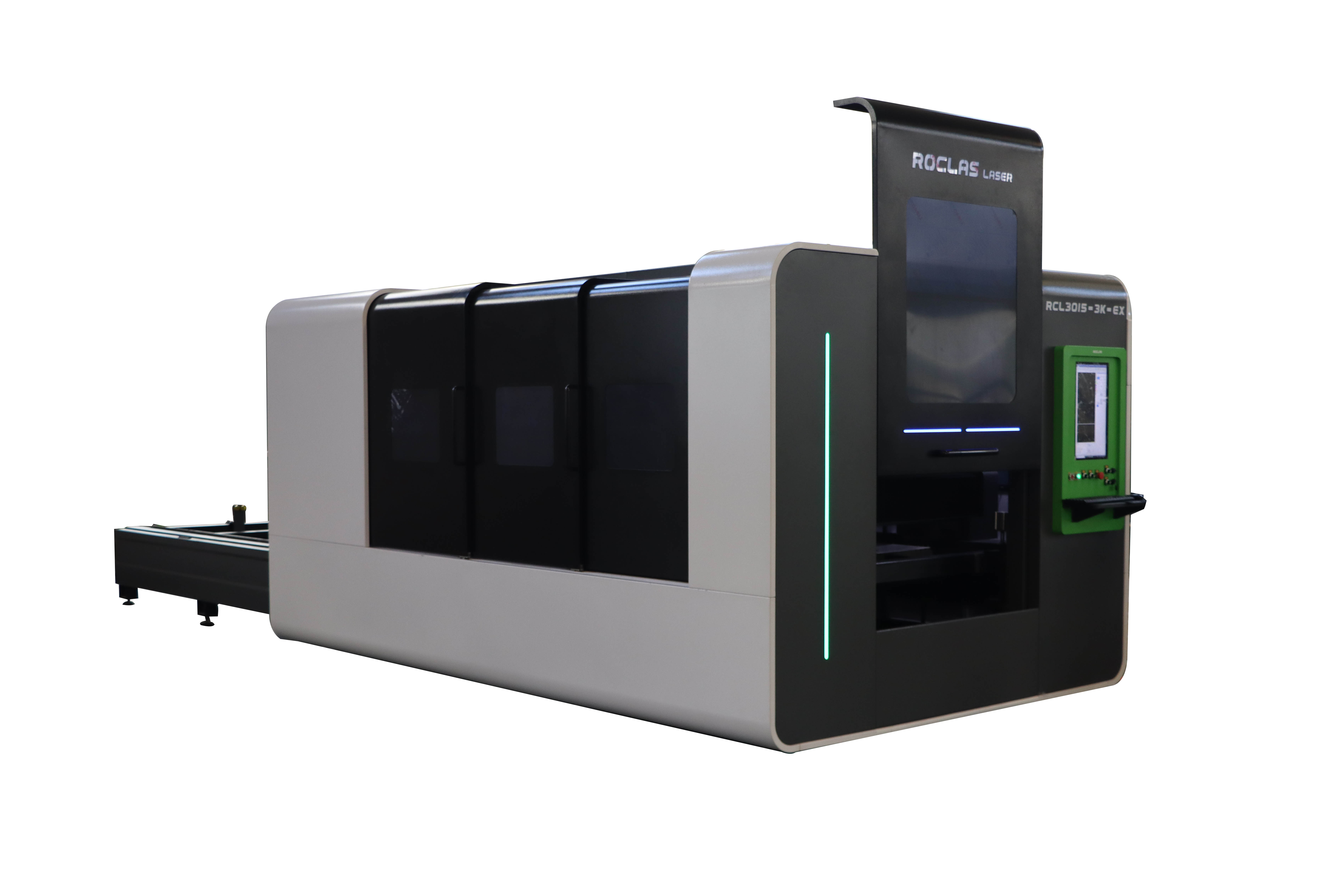

Starting a laser cutting shop can be a lucrative business opportunity, especially with the growing demand for precision-cut metal parts in industries like automotive, aerospace, and signage. To succeed, you need the right equipment, expertise, and strategy. Roclas, a leading brand in fiber laser cutting technology, provides high-performance machines that ensure efficiency, accuracy, and cost-effectiveness for your laser cutting business.

Why Choose a Fiber laser cutting machine?

Fiber laser cutting machines have revolutionized the metal fabrication industry due to their speed, precision, and low maintenance costs. Unlike traditional CO₂ lasers, fiber lasers use solid-state technology, making them more energy-efficient and capable of cutting reflective metals like copper and brass without damage.

Key Advantages of Roclas Fiber Laser Machines

1. High Speed & Precision – Roclas machines deliver fast cutting speeds with micron-level accuracy, ideal for intricate designs.

2. Low Operating Costs – With minimal consumables and energy-efficient operation, Roclas reduces long-term expenses.

3. Versatility – Capable of cutting stainless steel, aluminum, carbon steel, and more with superior edge quality.

4. User-Friendly Software – Roclas machines come with intuitive CNC controls, making them easy to operate even for beginners.

Steps to Launching Your Laser Cutting Shop

1. Market Research & Business Plan

Identify your target market—whether it’s industrial manufacturers, artisans, or small businesses. Analyze competitors and determine pricing strategies. A solid business plan should include startup costs, projected revenue, and marketing strategies.

2. Selecting the Right Roclas Machine

Roclas offers a range of fiber laser cutters, from compact models for small shops to industrial-grade machines for high-volume production. Consider factors like

- Work Area Size – Choose based on the maximum sheet size you plan to cut.

- Laser Power – Higher wattage (e.g., 1000W-6000W) allows for thicker material cutting.

- Automation Options – Roclas provides auto-loading/unloading systems to boost productivity.

3. Setting Up Your Workspace

Ensure your shop has

- Proper ventilation and fume extraction systems.

- Stable power supply and safety measures (fire extinguishers, protective gear).

- Organized material storage for efficient workflow.

4. Hiring & Training Staff

Even with Roclas’ easy-to-use machines, skilled operators can maximize efficiency. Provide training on machine maintenance, CAD/CAM software, and safety protocols.

5. Marketing Your Services

- Online Presence – Create a website showcasing your capabilities with sample projects.

- Social Media & SEO – Use platforms like Instagram and LinkedIn to attract clients.

- Networking – Partner with local manufacturers and attend trade shows.

Why Roclas is the Best Choice for Your Shop

Roclas stands out for its

- Reliability – Built with high-quality components for long-term durability.

- After-Sales Support – Comprehensive training, maintenance, and spare parts availability.

- Cutting-Edge Technology – Continuous innovation ensures your shop stays competitive.

Conclusion

A laser cutting shop can be a highly profitable venture with the right equipment and strategy. By investing in a Roclas fiber laser cutting machine, you ensure precision, efficiency, and scalability for your business. Whether you're a startup or an established fabricator, Roclas provides the technology and support to help you thrive in the competitive metal cutting industry.

Ready to start your laser cutting business? Contact Roclas today for the best fiber laser solutions!