Introduction

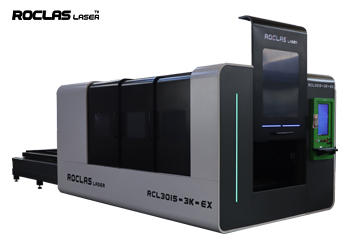

Fiber laser metal cutting machines have revolutionized the manufacturing and metal fabrication industries with their precision, speed, and efficiency. As demand for high-quality metal cutting solutions grows, businesses seek reliable, high-performance machines that enhance productivity. Among the top contenders in the market, Roclas stands out as a leading brand, offering cutting-edge fiber laser technology tailored for industrial applications.

What is a Fiber Laser Metal Cutting Machine?

A fiber laser metal cutting machine utilizes a high-intensity laser beam generated through fiber optics to cut through various metals, including steel, aluminum, copper, and brass. Unlike traditional CO₂ lasers, fiber lasers offer superior energy efficiency, faster cutting speeds, and lower maintenance requirements.

Key Advantages of Fiber laser cutting machines

1. High Precision & Accuracy – Fiber lasers produce a fine, concentrated beam that ensures clean, burr-free cuts with minimal material distortion.

2. Speed & Efficiency – These machines operate at significantly higher speeds than conventional cutting methods, boosting production output.

3. Low Operating Costs – With minimal power consumption and reduced maintenance, fiber lasers offer long-term cost savings.

4. Versatility – Capable of cutting a wide range of metals and thicknesses, fiber lasers are ideal for industries like automotive, aerospace, and construction.

5. Automation Compatibility – Many fiber laser machines, including Roclas models, support automated loading/unloading systems for seamless integration into smart factories.

Why Choose Roclas Fiber Laser Cutting Machines?

Roclas has established itself as a trusted name in laser cutting technology, delivering machines that combine innovation, durability, and performance. Here’s why Roclas is a top choice

- Advanced Fiber Laser Technology – Roclas machines feature high-power fiber laser sources (ranging from 500W to 20,000W) for superior cutting capabilities.

- User-Friendly Interface – Equipped with intuitive CNC controls, Roclas machines ensure easy operation and programming.

- Robust Construction – Built with high-quality components, Roclas machines guarantee long-term reliability even in demanding industrial environments.

- Customizable Solutions – Whether for thin sheet metal or thick plates, Roclas offers tailored solutions to meet diverse cutting needs.

- Global Support & Service – With a strong after-sales network, Roclas provides prompt technical support and maintenance services worldwide.

Applications of Roclas Fiber Laser Cutting Machines

Roclas fiber laser cutters are widely used in

- Automotive Manufacturing – Precision cutting of chassis, body panels, and exhaust systems.

- Aerospace Industry – Fabrication of lightweight, high-strength components.

- Metal Fabrication – Production of machinery parts, enclosures, and decorative metalwork.

- Electronics & Appliances – Cutting intricate components for electronic devices.

Conclusion

Investing in a Roclas fiber laser metal cutting machine means choosing speed, precision, and reliability for your business. As industries evolve, Roclas continues to lead with cutting-edge technology, ensuring manufacturers stay ahead in a competitive market.

For businesses seeking the best in laser cutting performance, Roclas delivers unmatched quality and efficiency. Explore Roclas’ range of fiber laser machines today and elevate your metal fabrication capabilities!