Introduction

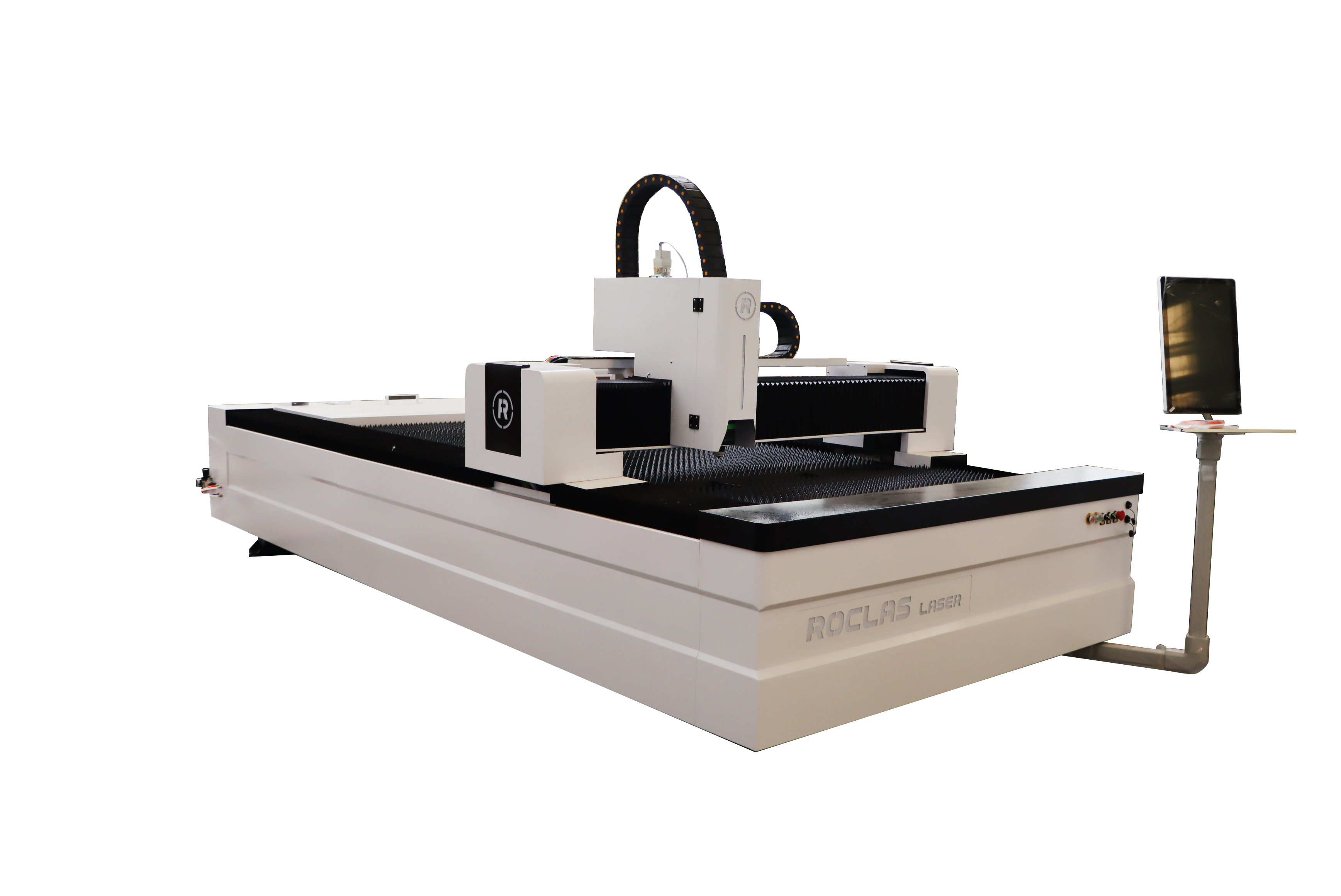

In the world of modern manufacturing, precision, speed, and efficiency are paramount. Roclas, a leading innovator in CNC laser technology, offers state-of-the-art fiber optic laser cutting systems designed to meet the demands of industries ranging from automotive to aerospace. These cutting-edge machines leverage high-power fiber lasers to deliver superior cutting accuracy, minimal material waste, and unmatched productivity.

Why Choose Roclas Fiber Optic Laser Cutting Systems?

Roclas Fiber laser cutting machines stand out due to their advanced technology, durability, and cost-effectiveness. Here’s why they are the preferred choice for manufacturers worldwide

1. High Precision & Speed

- Roclas fiber laser cutters utilize a focused laser beam for micron-level accuracy, ensuring clean cuts even on intricate designs.

- With cutting speeds up to 100 m/min, these machines significantly reduce production time while maintaining exceptional edge quality.

2. Versatility in Material Processing

- Whether cutting stainless steel, aluminum, copper, brass, or reflective metals, Roclas fiber laser systems handle a wide range of materials with ease.

- The non-contact cutting process minimizes material deformation, making it ideal for delicate or thin sheets.

3. Energy Efficiency & Low Maintenance

- Unlike CO₂ lasers, fiber lasers consume 30-50% less power, reducing operational costs.

- With no moving parts in the laser source, Roclas machines require minimal maintenance, ensuring long-term reliability.

4. Smart Automation Integration

- Roclas systems support automated loading/unloading, AI-based nesting software, and IoT connectivity for Industry 4.0-ready production lines.

Applications of Roclas Fiber Laser Cutting Machines

From industrial fabrication to artistic metalwork, Roclas fiber optic laser cutters excel in diverse applications

- Automotive Precision cutting of chassis components, exhaust systems, and body panels.

- Aerospace High-tolerance cutting for turbine blades and lightweight alloys.

- Electronics Micro-cutting for circuit boards and enclosures.

- Architectural Metalwork Custom designs for decorative panels and structural elements.

Conclusion

Roclas fiber optic laser cutting systems redefine manufacturing efficiency with their speed, precision, and adaptability. By investing in Roclas technology, businesses gain a competitive edge through reduced waste, lower energy costs, and superior cut quality.

Upgrade your production line with Roclas today—where innovation meets industrial excellence!

(Word count 450)

Would you like additional details on specific models or technical specifications? Let us know how we can assist further!