Introduction

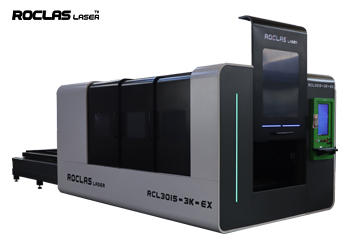

Investing in a Fiber laser cutting machine is a significant decision for any manufacturing or metal fabrication business. The cost of a fiber laser system depends on various factors, including power, brand, features, and application requirements. At Roclas, we specialize in high-performance fiber laser cutting solutions that balance affordability, precision, and durability. In this guide, we’ll break down the key factors influencing fiber laser costs and why Roclas stands out as the ideal choice for your business.

Factors Affecting Fiber Laser Cutting Machine Costs

1. Laser Power (Wattage)

The power of a fiber laser directly impacts its cutting speed and material thickness capacity. Machines with 500W to 6kW power are common in the market.

- Low-power (500W-1kW) Best for thin metals (up to 6mm), lower cost (~$20,000-$50,000).

- Mid-power (1.5kW-3kW) Handles thicker materials (up to 12mm), priced between $50,000-$100,000.

- High-power (4kW-6kW+) Cuts thick steel (up to 25mm), ideal for heavy-duty industries, costing $100,000-$300,000+.

Roclas Recommendation Our Roclas RFL-3000W offers an excellent balance of speed and affordability for medium-thickness materials.

2. Brand & Quality

Well-known brands like Roclas provide superior reliability, advanced technology, and better after-sales support compared to cheaper alternatives. While budget machines may cost less upfront, they often lead to higher maintenance expenses.

3. Cutting Bed Size & Configuration

- Small format (1.5m x 3m) Lower cost (~$30,000-$60,000).

- Large format (4m x 8m+) Higher cost (~$80,000-$200,000+).

Roclas offers customizable bed sizes to fit different production needs.

4. Automation & Additional Features

- Automatic loading/unloading systems increase efficiency but add $20,000-$50,000 to the price.

- High-precision cutting heads (e.g., Raytools, Precitec) improve accuracy but cost extra.

- Software integration (e.g., CAD/CAM compatibility) enhances workflow but may require additional investment.

Roclas Advantage Our machines come with user-friendly software and optional automation upgrades for seamless operation.

5. Maintenance & Operating Costs

- Consumables (e.g., lenses, nozzles) add $1,000-$5,000/year.

- Electricity consumption varies by power (e.g., 3kW machines use ~15-20kWh).

- Cooling systems (air or water-cooled) affect long-term costs.

Roclas fiber lasers are designed for low energy consumption and minimal maintenance, reducing total cost of ownership.

Why Choose Roclas Fiber Laser Cutting Machines?

- High Precision & Speed Our lasers deliver micron-level accuracy and fast cutting speeds, improving productivity.

- Durability Built with industrial-grade components for long-term reliability.

- Competitive Pricing We offer cost-effective solutions without compromising quality.

- Global Support Roclas provides 24/7 technical assistance and spare parts availability.

Conclusion

The cost of a fiber laser cutting machine depends on power, features, and brand reputation. While initial investment matters, long-term efficiency and reliability are crucial. Roclas provides high-quality, affordable fiber laser solutions tailored to your business needs.

Contact Roclas today for a customized quote and discover the best fiber laser cutting machine for your budget!

---

Word Count ~550

This article provides a detailed breakdown of fiber laser costs while promoting Roclas as a trusted brand. Let me know if you'd like any modifications!