When investing in a Fiber laser cutting machine, understanding the price factors is crucial for making an informed decision. The cost of these machines can vary significantly based on several key elements, including power output, brand reputation, machine size, and additional features. In this article, we’ll explore what influences the price of fiber laser cutting machines and why Roclas stands out as a top choice for businesses seeking high-quality, cost-effective solutions.

1. Laser Power and Cutting Capacity

One of the primary factors affecting the price of a fiber laser cutting machine is its power output, measured in watts (W). Machines with higher wattage (e.g., 3kW, 6kW, or 12kW) can cut thicker and more durable materials at faster speeds, making them ideal for industrial applications. However, higher power also means a higher price tag.

For businesses working with thin to medium-thickness metals (up to 15mm), a lower-power machine (1kW–3kW) from Roclas may offer the perfect balance between performance and affordability.

2. Brand and Manufacturing Quality

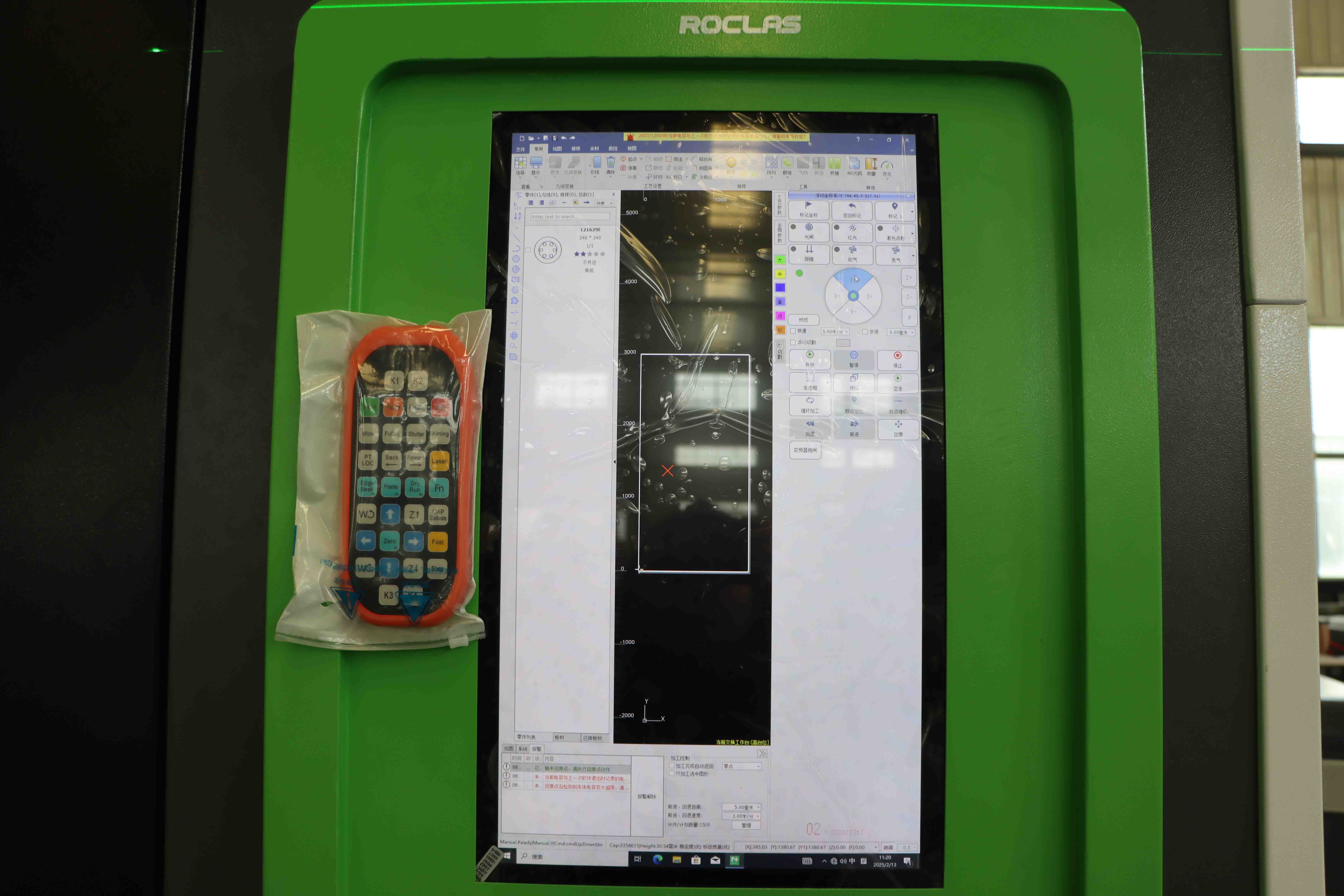

Not all fiber laser machines are created equal. Established brands like Roclas invest in advanced technology, premium components, and rigorous quality control to ensure long-term reliability. While cheaper, no-name brands may seem attractive initially, they often lack durability and after-sales support, leading to higher long-term costs.

Roclas machines are built with high-performance fiber laser sources (such as IPG or Raycus), precision cutting heads, and robust CNC systems, ensuring efficiency and minimal maintenance costs.

3. Machine Size and Work Area

The size of the cutting bed directly impacts the price. Larger work areas (e.g., 4m x 2m or 6m x 3m) allow for processing bigger sheets but require more structural reinforcement and higher manufacturing costs. Roclas offers customizable bed sizes to match different production needs, ensuring businesses only pay for the capacity they require.

4. Automation and Additional Features

Automation features such as automatic loading/unloading systems, pallet changers, and advanced CNC software can significantly increase the price but also improve productivity. Roclas provides optional upgrades like these to enhance workflow efficiency, making them a smart investment for high-volume manufacturers.

5. After-Sales Support and Warranty

A lower-priced machine may lack proper technical support or warranty coverage, leading to unexpected downtime and repair costs. Roclas offers comprehensive after-sales service, including installation, training, and maintenance, ensuring smooth operations and maximizing ROI.

Why Choose Roclas?Roclas fiber laser cutting machines provide an excellent balance of performance, durability, and affordability. With competitive pricing, industry-leading technology, and reliable customer support, Roclas ensures businesses get the best value for their investment.

The price of a fiber laser cutting machine depends on multiple factors, including power, brand, size, and features. By choosing Roclas, businesses gain access to high-quality, cost-efficient solutions backed by expert support. Whether you need a compact machine for small-scale production or an industrial-grade system, Roclas has the right option for you.

For a customized quote, contact Roclas today and discover the perfect fiber laser cutting solution for your needs!