Introduction

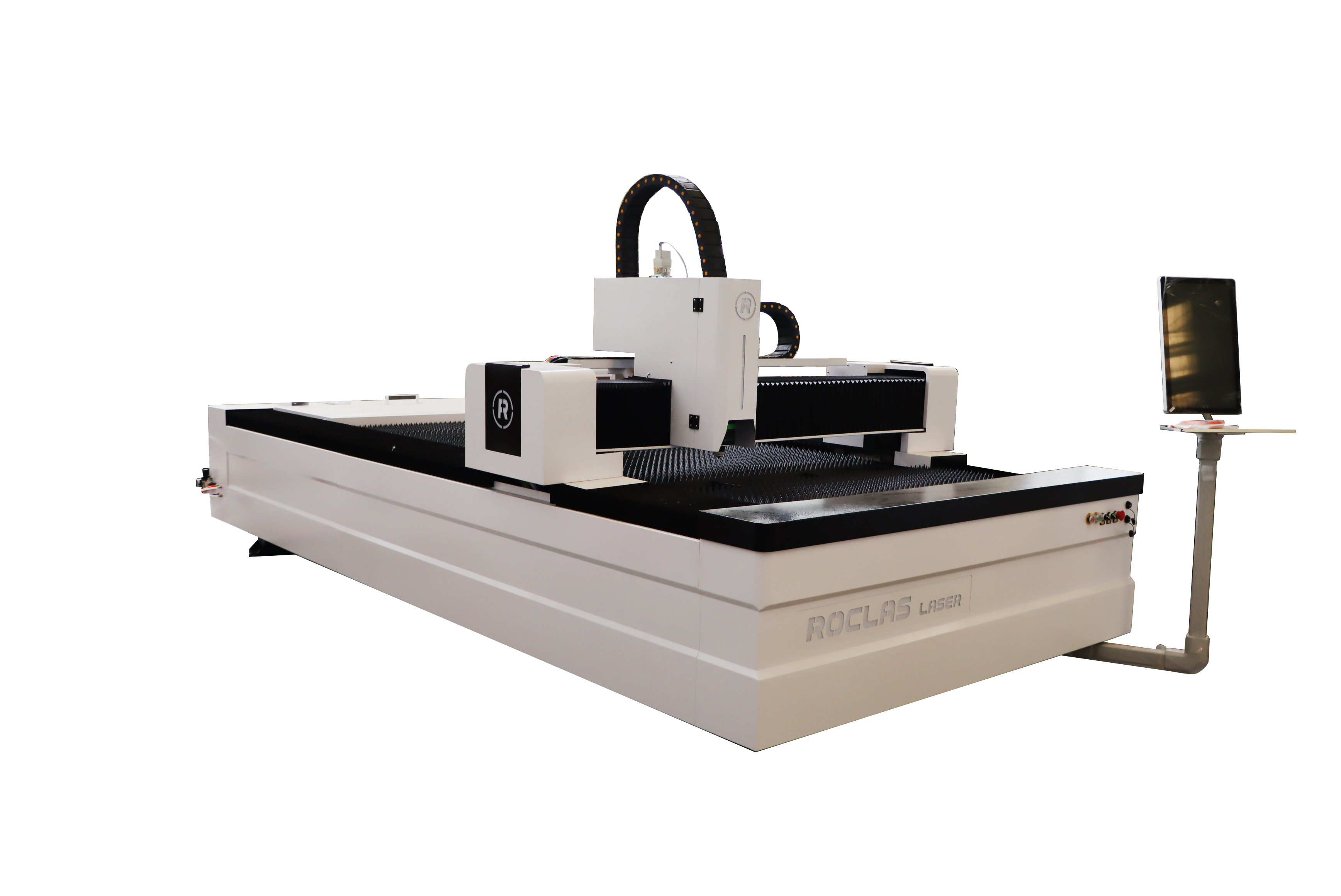

Laser cutting has revolutionized the metal fabrication industry, offering unparalleled precision, speed, and versatility. Among the leading brands in this field, Roclas stands out with its advanced Fiber laser cutting machines, designed to meet the demands of modern manufacturing. Whether you're working with steel, aluminum, brass, or other metals, Roclas laser cutters ensure high-quality results with minimal waste.

Why Choose Laser Cutting for Metal Fabrication?

Traditional metal cutting methods, such as plasma or waterjet cutting, often struggle with intricate designs and thin materials. Laser cutting, however, provides

- Exceptional Precision – Capable of cutting complex shapes with tight tolerances (±0.1mm).

- High Speed – Faster than mechanical cutting, reducing production time.

- Minimal Material Waste – Optimized cutting paths save raw materials.

- Smooth Edge Quality – No burrs or deformations, reducing post-processing needs.

Roclas Fiber Laser Cutting Machines The Industry Leader

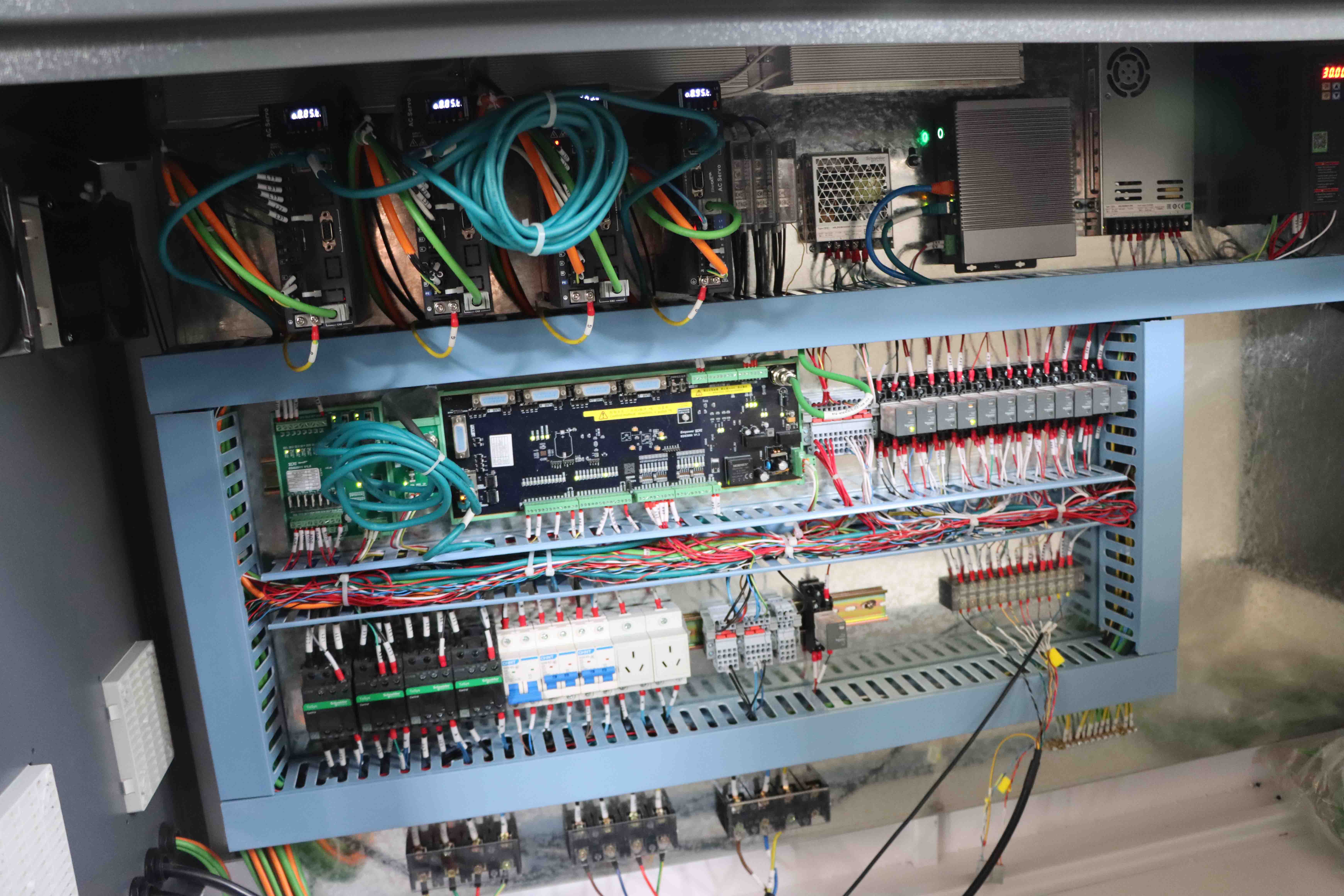

Roclas specializes in high-power fiber laser cutting systems, offering

1. Superior Beam Quality – Ensures clean cuts even on reflective metals like copper and brass.

2. Automated Operation – Features like automatic nozzle changing and material handling improve efficiency.

3. Energy Efficiency – Consumes less power compared to CO₂ lasers, lowering operational costs.

4. Low Maintenance – Solid-state fiber lasers have fewer moving parts, ensuring long-term reliability.

Applications in Metal Fabrication

Roclas laser cutters are widely used in industries such as

- Automotive – Precision parts with complex geometries.

- Aerospace – Lightweight yet durable components.

- Construction – Structural steel and decorative metalwork.

- Electronics – Fine-cutting for enclosures and heat sinks.

Conclusion

For businesses seeking high-performance laser cutting in metal fabrication, Roclas fiber laser machines provide the perfect solution. With cutting-edge technology, efficiency, and durability, Roclas helps manufacturers stay competitive in a fast-evolving industry.

Upgrade your production line with Roclas today and experience the future of metal fabrication!

(Word count 450)