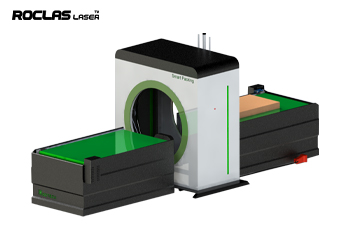

Fiber laser cutting machines have revolutionized the metal fabrication industry with their precision, speed, and efficiency. As a leading brand in laser technology, Roclas provides high-performance fiber laser cutting machines that cater to various industrial needs. But how exactly do these machines work? In this article, we will explore the working principle of fiber laser cutting machines and why Roclas stands out in this competitive market.

The Core Principle of Fiber Laser Cutting

Fiber laser cutting machines utilize a high-intensity laser beam generated by an optical fiber doped with rare-earth elements such as ytterbium. The laser beam is amplified within the fiber optic cable and then directed through a series of mirrors and lenses to focus on the workpiece.

The key steps in the fiber laser cutting process include

1. Laser Generation – A diode pump source excites the doped fiber, producing a concentrated laser beam.

2. Beam Delivery – The laser beam travels through a flexible fiber optic cable, ensuring minimal energy loss.

3. Focusing the Beam – A cutting head equipped with lenses focuses the laser to an extremely fine point, increasing its intensity.

4. Material Interaction – The focused laser beam melts, burns, or vaporizes the material, while an assist gas (such as nitrogen or oxygen) blows away the molten residue, creating a clean cut.

Advantages of Fiber Laser Cutting Machines

Compared to traditional CO₂ laser cutters, fiber laser cutting machines offer several benefits

- Higher Efficiency – Fiber lasers convert up to 50% of electrical energy into laser light, making them more energy-efficient.

- Superior Precision – The fine laser beam allows for intricate cuts with minimal kerf width, ideal for detailed designs.

- Faster Cutting Speeds – Fiber lasers can cut thin to medium-thickness metals at much higher speeds than CO₂ lasers.

- Lower Maintenance – With no moving mirrors or complex optics, fiber laser machines require less upkeep.

Why Choose Roclas Fiber Laser Cutting Machines?

Roclas is a trusted name in laser cutting technology, offering machines that combine innovation, reliability, and affordability. Here’s why Roclas stands out

✔ Advanced Fiber Laser Technology – Roclas machines use high-quality fiber laser sources for consistent performance.

✔ User-Friendly Operation – Intuitive CNC controls make programming and operation seamless.

✔ Durability & Longevity – Built with robust materials, Roclas machines ensure long-term productivity.

✔ Custom Solutions – Whether for automotive, aerospace, or sheet metal fabrication, Roclas provides tailored solutions.

Understanding the working principle of fiber laser cutting machines helps businesses make informed decisions when investing in this technology. With superior efficiency, precision, and speed, fiber lasers are the future of metal cutting. Roclas delivers top-tier fiber laser cutting machines designed to enhance productivity and reduce operational costs.

For businesses looking to upgrade their cutting capabilities, Roclas offers the perfect blend of performance and affordability. Contact us today to explore our range of fiber laser cutting solutions!