Introduction

Sheet metal laser cutters have revolutionized the manufacturing industry, offering precision, speed, and versatility in cutting various metals. Whether for industrial fabrication, automotive parts, or intricate decorative designs, laser cutting technology ensures high-quality results. Among the top brands in this field, Roclas stands out with its advanced Fiber laser cutting machines, delivering unmatched performance and reliability.

What is a Sheet Metal Laser Cutter?

A sheet metal laser cutter is a CNC (Computer Numerical Control) machine that uses a high-powered laser beam to cut through metal sheets with extreme accuracy. Unlike traditional mechanical cutting methods, laser cutting minimizes material waste, reduces production time, and allows for complex designs.

There are two main types of laser cutters for sheet metal

1. CO2 Laser Cutters – Suitable for thicker materials but less efficient for reflective metals.

2. Fiber Laser Cutters – More energy-efficient, faster, and ideal for cutting thin to medium-thickness metals, including stainless steel, aluminum, and copper.

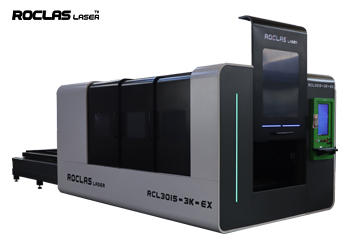

Why Choose Roclas Fiber Laser Cutting Machines?

Roclas specializes in high-performance fiber laser cutting machines, designed to meet the demands of modern manufacturing. Here’s why Roclas should be your preferred choice

1. Superior Precision & Speed

Roclas machines utilize advanced fiber laser technology, ensuring micron-level precision even for intricate designs. With cutting speeds up to 120m/min, they significantly boost productivity while maintaining accuracy.

2. Energy Efficiency & Low Maintenance

Unlike CO2 lasers, Roclas fiber lasers consume less power and have a longer lifespan, reducing operational costs. Their solid-state design minimizes maintenance requirements, ensuring continuous production with minimal downtime.

3. Wide Material Compatibility

From stainless steel and aluminum to brass and copper, Roclas laser cutters handle a variety of metals effortlessly. Their high-intensity laser beams ensure clean cuts without burrs or deformations.

4. User-Friendly CNC Control

Roclas integrates intuitive CNC control systems, allowing operators to program complex cutting paths easily. The software supports DXF, DWG, and AI file formats, making it compatible with most design programs.

5. Durability & Reliability

Built with high-quality components, Roclas machines are designed for long-term industrial use. Their robust structure ensures stability, even during high-speed cutting operations.

Applications of Roclas Sheet Metal Laser Cutters

- Automotive Industry – Precision cutting for car body parts, exhaust systems, and brackets.

- Aerospace – Manufacturing lightweight yet durable components.

- Architecture & Decoration – Creating intricate metal artworks, signage, and façades.

- Electronics – Cutting precise enclosures and heat sinks.

Conclusion

Investing in a Roclas fiber laser cutting machine means choosing speed, precision, and reliability for your sheet metal fabrication needs. Whether you're a small workshop or a large-scale manufacturer, Roclas provides the technology to enhance efficiency and product quality.

Upgrade your production line with Roclas today and experience the future of laser cutting!

(Word count 510)