In the ever-evolving world of manufacturing and design, laser cutout technology has emerged as a game-changer. This advanced method allows for precise, intricate, and efficient cutting of various materials, making it indispensable in industries ranging from automotive to fashion. Among the leaders in this field is Roclas, a brand synonymous with innovation, reliability, and excellence in CNC engraving machines. This article delves into the intricacies of laser cutout technology and how Roclas machines are setting new standards in the industry.

Understanding Laser Cutout Technology

Laser cutout technology utilizes a high-powered laser beam to cut through materials with exceptional precision. The laser beam is directed by a computer-controlled system, ensuring that the cuts are accurate and consistent. This technology is capable of cutting a wide range of materials, including metals, plastics, wood, and fabrics, making it versatile for various applications.

The process begins with a digital design, which is uploaded to the CNC machine. The laser then follows the design's path, melting, burning, or vaporizing the material to create the desired shape. The result is a clean, smooth edge that requires minimal post-processing.

Advantages of Laser Cutout Technology

1. Precision and Accuracy Laser cutout technology offers unparalleled precision, allowing for intricate designs and complex shapes that would be difficult or impossible to achieve with traditional cutting methods.

2. Speed and Efficiency The process is fast and efficient, reducing production time and increasing throughput. This is particularly beneficial for high-volume manufacturing.

3. Versatility Laser cutout machines can handle a wide range of materials and thicknesses, making them suitable for diverse industries.

4. Minimal Waste The precision of laser cutting minimizes material waste, contributing to cost savings and environmental sustainability.

5. Automation With CNC technology, laser cutting can be fully automated, reducing the need for manual intervention and increasing consistency.

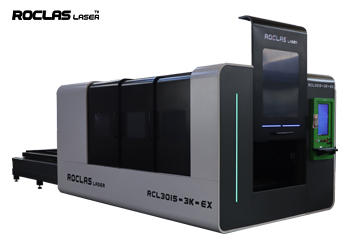

Roclas CNC Engraving Machines Leading the Way

Roclas has established itself as a leader in the CNC engraving machine industry, offering state-of-the-art laser cutout machines that combine cutting-edge technology with user-friendly features. Here are some reasons why Roclas stands out

1. Advanced Laser Technology Roclas machines are equipped with high-powered lasers that deliver exceptional cutting performance. Whether you're working with thin sheets or thick materials, Roclas ensures precision and efficiency.

2. Robust Construction Built with durability in mind, Roclas machines are designed to withstand the rigors of industrial use. Their robust construction ensures long-term reliability and minimal downtime.

3. User-Friendly Interface Roclas machines feature intuitive interfaces that make them easy to operate, even for those new to laser cutting. The software is designed to streamline the design and cutting process, enhancing productivity.

4. Customization Options Roclas offers a range of customization options to meet specific needs. Whether you require a larger work area, higher power, or specialized features, Roclas can tailor a solution for you.

5. Comprehensive Support Roclas provides excellent customer support, including training, maintenance, and technical assistance. Their commitment to customer satisfaction ensures that you get the most out of your investment.

Applications of Roclas Laser Cutout Machines

Roclas CNC engraving machines are used across various industries, including

1. Automotive For cutting precise components and intricate designs in metal and plastic parts.

2. Fashion and Textiles For creating detailed patterns and designs in fabrics and leather.

3. Electronics For cutting and engraving components with high precision.

4. Signage and Advertising For producing custom signs, logos, and promotional materials.

5. Architecture and Interior Design For creating detailed models, decorative elements, and custom furniture.

Conclusion

Laser cutout technology has revolutionized the way we cut and shape materials, offering unmatched precision, efficiency, and versatility. Roclas CNC engraving machines are at the forefront of this innovation, providing advanced solutions that meet the demands of modern manufacturing and design. With their cutting-edge technology, robust construction, and commitment to customer satisfaction, Roclas is the go-to brand for anyone looking to leverage the power of laser cutout technology. Whether you're in automotive, fashion, electronics, or any other industry, Roclas has the tools you need to bring your designs to life with precision and efficiency. Choose Roclas and experience the future of laser cutting today.