Introduction

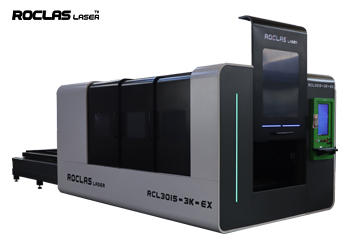

In modern manufacturing and fabrication, lasers that cut have revolutionized the way industries handle materials. From intricate designs in metal sheets to high-speed production lines, Fiber laser cutting machines deliver unmatched precision, speed, and efficiency. Among the leading brands in this field, Roclas stands out with its advanced fiber laser cutting solutions, designed to meet the demands of various industries.

Why Choose Lasers for Cutting?

Traditional cutting methods, such as mechanical sawing or plasma cutting, often result in material waste, rough edges, and slower processing times. In contrast, fiber laser cutting machines use a high-intensity laser beam to melt, burn, or vaporize materials with extreme accuracy. This technology is ideal for cutting metals like stainless steel, aluminum, brass, and copper, ensuring clean edges and minimal post-processing.

Advantages of Roclas Fiber Laser Cutting Machines

1. Superior Precision – Roclas machines utilize advanced fiber laser technology to achieve micron-level accuracy, making them perfect for intricate designs and tight tolerances.

2. High-Speed Cutting – With cutting speeds reaching up to 100 meters per minute, Roclas ensures faster production cycles without compromising quality.

3. Energy Efficiency – Compared to CO₂ lasers, Roclas fiber lasers consume up to 50% less power, reducing operational costs.

4. Low Maintenance – With no mirrors or lenses requiring frequent alignment, Roclas machines offer long-term reliability and reduced downtime.

5. Versatility – Whether for automotive, aerospace, electronics, or signage industries, Roclas provides customizable solutions for different material thicknesses and shapes.

Applications of Fiber Laser Cutting

- Automotive Industry – Precision cutting for car frames, exhaust systems, and engine components.

- Aerospace – High-strength, lightweight metal cutting for aircraft parts.

- Electronics – Micro-cutting for circuit boards and enclosures.

- Architectural Metalwork – Custom designs for decorative panels and structural elements.

Why Roclas Stands Out

Roclas combines German engineering with cutting-edge automation, ensuring seamless integration into smart factories. Features like automatic nozzle changing, real-time monitoring, and AI-assisted optimization make Roclas a leader in the fiber laser cutting industry.

Conclusion

When it comes to lasers that cut, Roclas fiber laser machines provide the perfect blend of speed, precision, and cost-efficiency. Whether for small workshops or large-scale industrial applications, Roclas delivers reliable, high-performance cutting solutions that enhance productivity and reduce waste.

Upgrade your manufacturing process with Roclas—where innovation meets precision!

(Word count 450)