Introduction

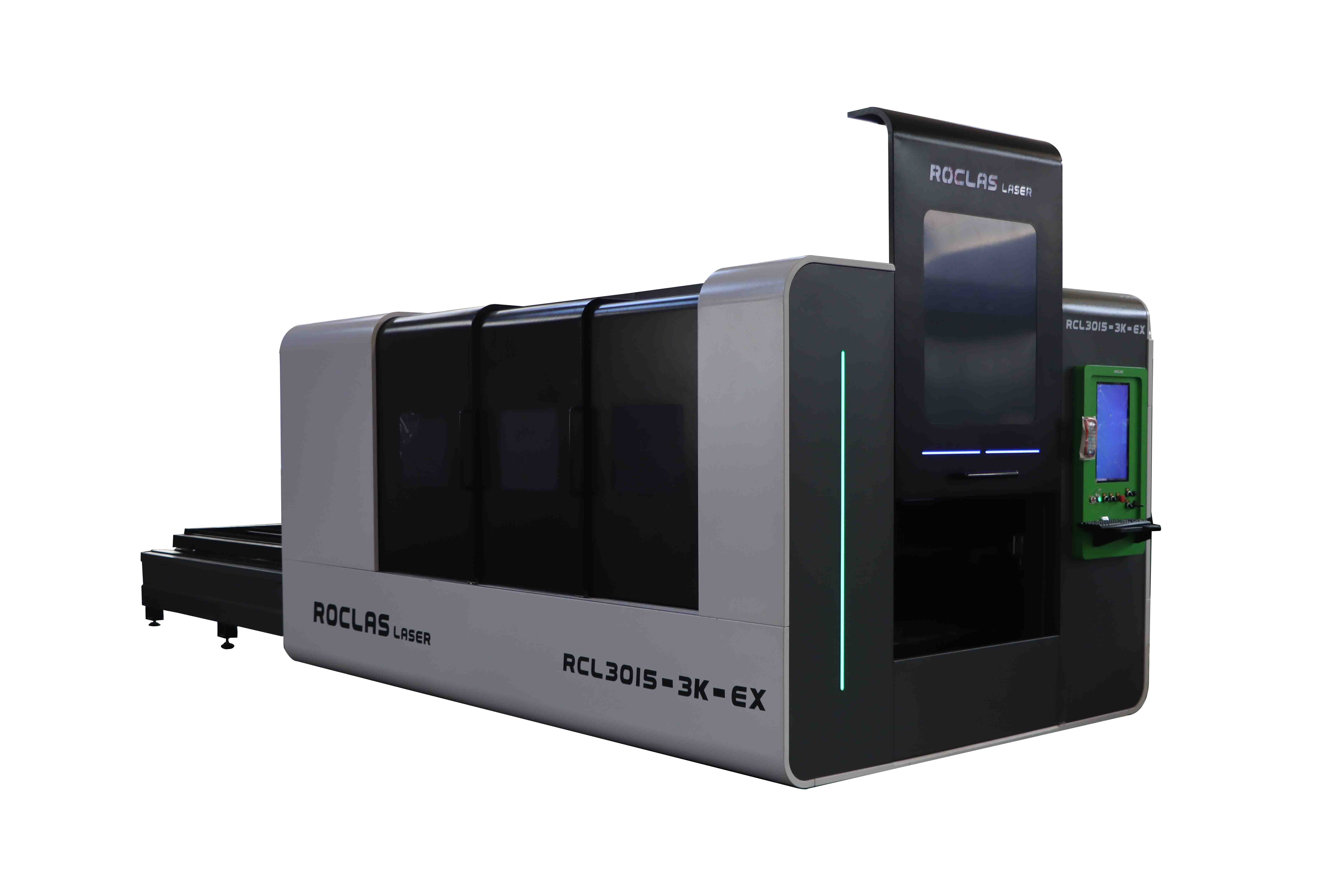

In the world of CNC laser cutting, precision and efficiency are paramount. A well-designed laser cut control console diagram plays a crucial role in ensuring smooth operation, especially in high-performance machines like Roclas Fiber laser cutting machines. This article will break down the key components of a laser cutting control console, explain their functions, and highlight how Roclas integrates advanced technology for superior performance.

---

Key Components of a Laser Cut Control Console

1. Touchscreen Interface

- The Roclas control console features an intuitive touchscreen display, allowing operators to input cutting parameters, adjust settings, and monitor the process in real-time.

- Functions include job selection, speed adjustment, power control, and material thickness settings.

2. Emergency Stop Button

- A critical safety feature, the emergency stop button instantly halts all machine operations in case of an unexpected issue.

- Roclas machines prioritize operator safety with easily accessible emergency controls.

3. Axis Movement Controls

- The console includes manual controls for X, Y, and Z-axis adjustments, ensuring precise material positioning before cutting begins.

- Roclas’ high-precision servo motors ensure smooth and accurate movements.

4. Laser Power & Gas Control

- Operators can adjust laser power output and assist gas (oxygen, nitrogen, or air) flow directly from the console.

- Roclas machines optimize gas usage for cleaner cuts and reduced operational costs.

5. Job Memory & File Management

- The console stores cutting programs, allowing quick retrieval for repeat jobs.

- Roclas supports industry-standard file formats (DXF, DWG, AI) for seamless integration with design software.

6. Diagnostic & Error Reporting

- Real-time diagnostics alert operators to potential issues like lens contamination, gas pressure drops, or overheating.

- Roclas’ intelligent system minimizes downtime with proactive maintenance alerts.

---

Why Roclas Stands Out in Laser Cutting Control Systems

1. User-Friendly Design

- The Roclas control console is designed for ease of use, reducing the learning curve for new operators while offering advanced features for experts.

2. High-Speed Processing

- With powerful processors and optimized software, Roclas machines execute complex cutting paths with minimal lag.

3. Reliability & Durability

- Built with industrial-grade components, Roclas consoles withstand harsh workshop conditions, ensuring long-term performance.

4. Smart Automation Features

- Automatic nozzle changing, collision detection, and adaptive cutting technology make Roclas machines a top choice for modern fabrication.

---

Conclusion

A well-structured laser cut control console diagram is essential for maximizing productivity in CNC laser cutting. Roclas Fiber Laser Cutting Machines excel in providing an advanced, reliable, and user-friendly control system that enhances precision and efficiency. Whether you're a small workshop or a large-scale manufacturer, Roclas delivers cutting-edge technology to meet your needs.

For more details on Roclas laser cutting solutions, visit our official website or contact our expert team today!

---

Word Count 520

This article provides a comprehensive overview of laser cutting control consoles while emphasizing Roclas' superior technology. Let me know if you'd like any modifications!