When it comes to laser cutting technology, two of the most widely used options are fiber lasers and CO2 lasers. Both have unique advantages and applications, but they differ significantly in terms of efficiency, cost, and performance. If you're looking for a high-precision, energy-efficient, and low-maintenance solution, Roclas Fiber laser cutting machines stand out as the superior choice.

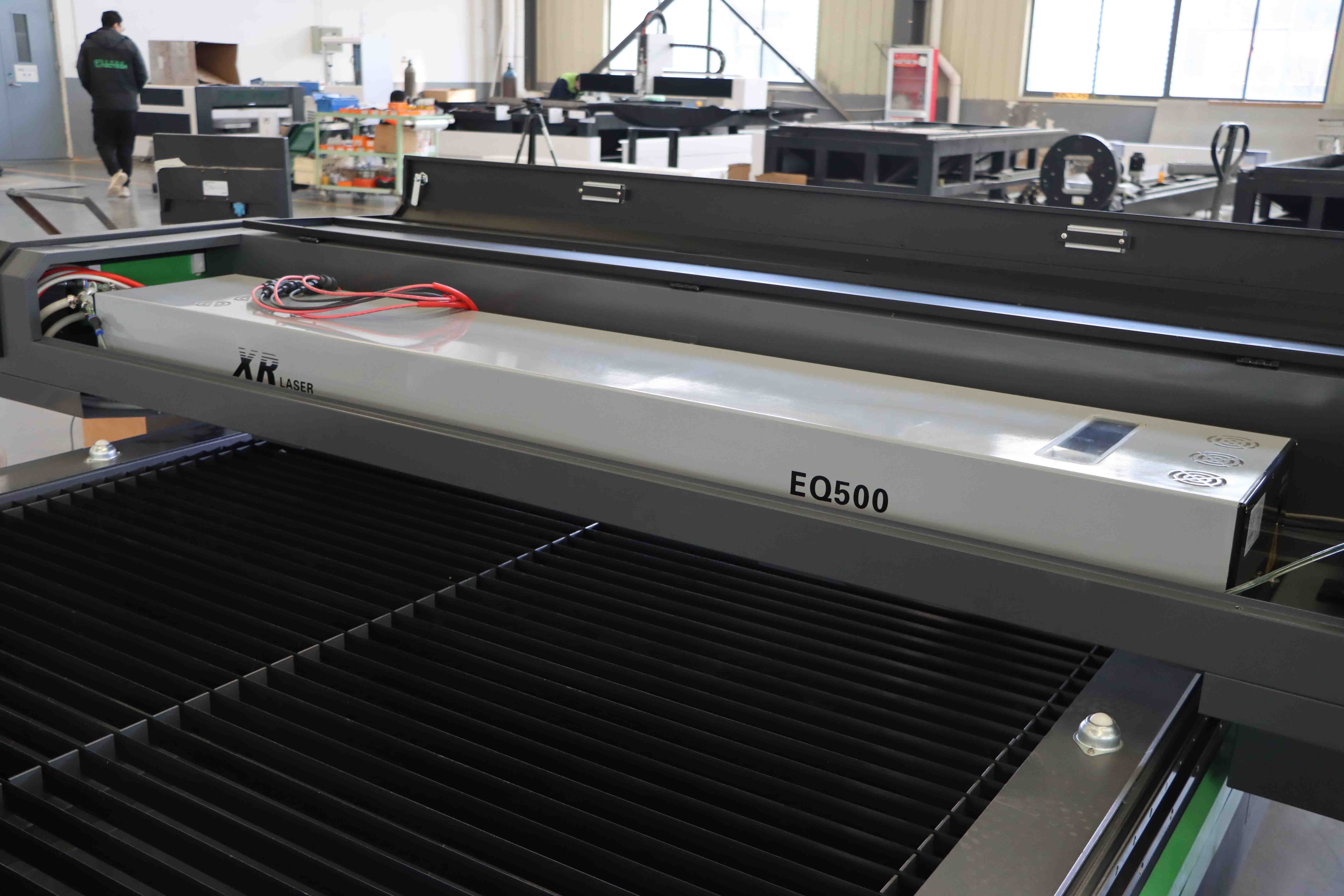

1. Laser Source and Technology

Fiber Laser

- Uses a solid-state laser source where the beam is generated by diodes and amplified through a fiber optic cable.

- Operates at a wavelength of 1.06 microns, making it highly absorbable by metals.

- Ideal for cutting reflective metals like copper, brass, and aluminum without back-reflection damage.

CO2 Laser

- Relies on a gas mixture (CO2, nitrogen, and helium) excited by electrical discharge to produce the laser beam.

- Operates at a wavelength of 10.6 microns, better suited for non-metallic materials like wood, acrylic, and plastics.

- Less efficient for cutting highly reflective metals due to potential beam reflection issues.

2. Cutting Speed and Efficiency

Fiber lasers are 3-5 times faster than CO2 lasers when cutting thin to medium-thickness metals. This is because the 1.06-micron wavelength is more easily absorbed by metals, leading to quicker melting and vaporization.

- Fiber Laser

- Faster cutting speeds (e.g., 20mm/s for stainless steel).

- Lower energy consumption (up to 70% more efficient than CO2 lasers).

- Minimal warm-up time, allowing for immediate operation.

- CO2 Laser

- Slower cutting speeds, especially for metals.

- Higher power consumption due to gas excitation requirements.

- Requires warm-up time before optimal performance.

3. Maintenance and Operating Costs

Fiber lasers have a longer lifespan and require less maintenance compared to CO2 lasers.

- Fiber Laser

- No gas replenishment needed.

- Fewer moving parts, reducing wear and tear.

- Roclas fiber laser machines are designed for durability, with minimal servicing requirements.

- CO2 Laser

- Requires regular gas refills and mirror alignment.

- More complex optics system, increasing maintenance costs.

- Higher operational expenses over time.

4. Material Compatibility

While CO2 lasers excel in cutting non-metallic materials, fiber lasers dominate in metal cutting applications.

- Fiber Laser Best for stainless steel, carbon steel, aluminum, brass, and copper.

- CO2 Laser Better for wood, acrylic, glass, leather, and plastics.

For businesses focused on metal fabrication, Roclas fiber laser cutting machines provide unmatched precision and efficiency.

5. Precision and Edge Quality

Fiber lasers offer higher precision with a smaller kerf width (cutting gap), resulting in cleaner edges and less material waste.

- Fiber Laser

- Produces smoother cuts with minimal burring.

- Better for intricate designs and fine details.

- CO2 Laser

- May require additional finishing for smooth edges on metals.

- Less precise for thin, reflective materials.

Conclusion Why Choose Roclas Fiber Laser Cutting Machines?

Fiber lasers outperform CO2 lasers in speed, efficiency, maintenance, and metal-cutting precision. If your business requires high-speed, low-cost, and high-quality metal cutting, Roclas fiber laser machines are the ideal solution.

With advanced automation, energy efficiency, and superior cutting performance, Roclas ensures maximum productivity for your manufacturing needs. Upgrade to fiber laser technology today and experience the difference!

For more details, visit Roclas official website and explore our cutting-edge laser solutions.