Introduction

Fiber laser cutting machines have revolutionized the manufacturing and metalworking industries with their precision, speed, and versatility. As a leading brand in laser technology, Roclas provides high-performance fiber laser cutting machines capable of processing a wide range of materials. Whether you're in automotive, aerospace, or general fabrication, understanding which materials a fiber laser can cut is essential for optimizing production efficiency.

1. Metals The Primary Focus of Fiber Lasers

Fiber lasers excel at cutting various metals, making them indispensable in industrial applications.

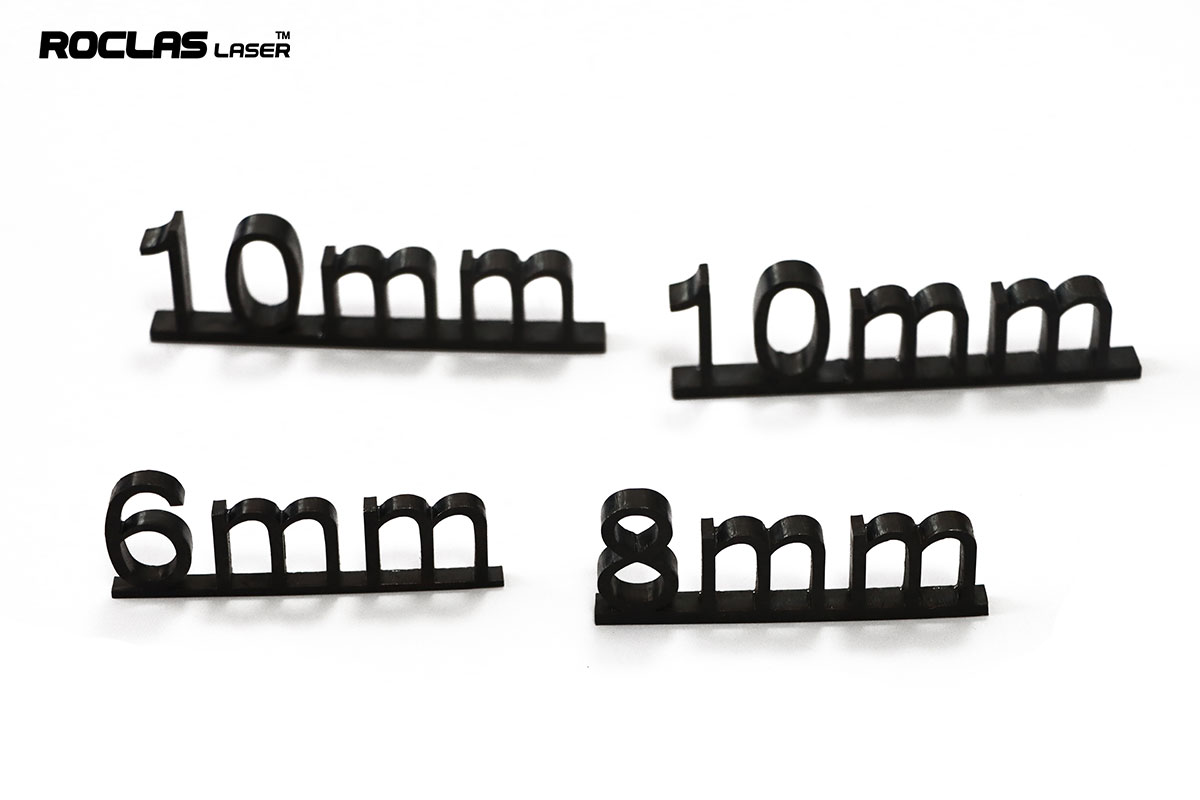

- Carbon Steel – Fiber lasers can easily cut low to high-carbon steel with excellent edge quality. Roclas machines ensure smooth, burr-free cuts even on thick plates.

- Stainless Steel – Highly reflective metals like stainless steel are efficiently processed by fiber lasers, maintaining corrosion resistance and precision.

- Aluminum – Although aluminum is highly reflective, advanced fiber lasers from Roclas can cut it cleanly, making them ideal for aerospace and automotive parts.

- Copper & Brass – These conductive metals can be challenging, but Roclas’ high-power fiber lasers deliver clean cuts with minimal heat distortion.

- Titanium – Used in medical and aerospace industries, titanium is precisely cut by fiber lasers without compromising material integrity.

2. Non-Metallic Materials (Limited Applications)

While fiber lasers are primarily designed for metals, they can also process certain non-metallic materials

- Plastics & Acrylics – Some fiber lasers can cut thin plastics, though CO₂ lasers are generally more suitable for these materials.

- Ceramics & Composites – Specialized fiber lasers can engrave or cut ceramics, but care must be taken to avoid cracking.

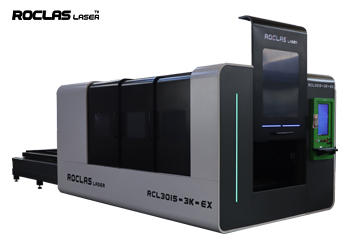

3. Why Choose Roclas Fiber Laser Cutting Machines?

Roclas stands out in the fiber laser industry due to

- High Precision & Speed – Advanced beam quality ensures fast, accurate cuts even on complex designs.

- Energy Efficiency – Consumes less power compared to CO₂ lasers, reducing operational costs.

- Low Maintenance – Solid-state fiber lasers have fewer moving parts, ensuring long-term reliability.

- Versatility – From thin sheets to thick plates, Roclas machines handle diverse materials effortlessly.

Conclusion

Fiber laser cutting machines, especially those from Roclas, offer unmatched versatility in processing metals like steel, aluminum, and titanium while also handling some non-metallic materials. Investing in a Roclas fiber laser ensures high efficiency, precision, and cost-effectiveness for your cutting needs.

For more details on how Roclas can enhance your production capabilities, visit our website or contact our expert team today!