Brass is a popular material in various industries due to its excellent machinability, corrosion resistance, and aesthetic appeal. Many manufacturers and hobbyists wonder whether a Fiber laser cutting machine can effectively cut brass. The answer is yes, but there are important factors to consider for optimal results.

How Does a Fiber Laser Cut Brass?

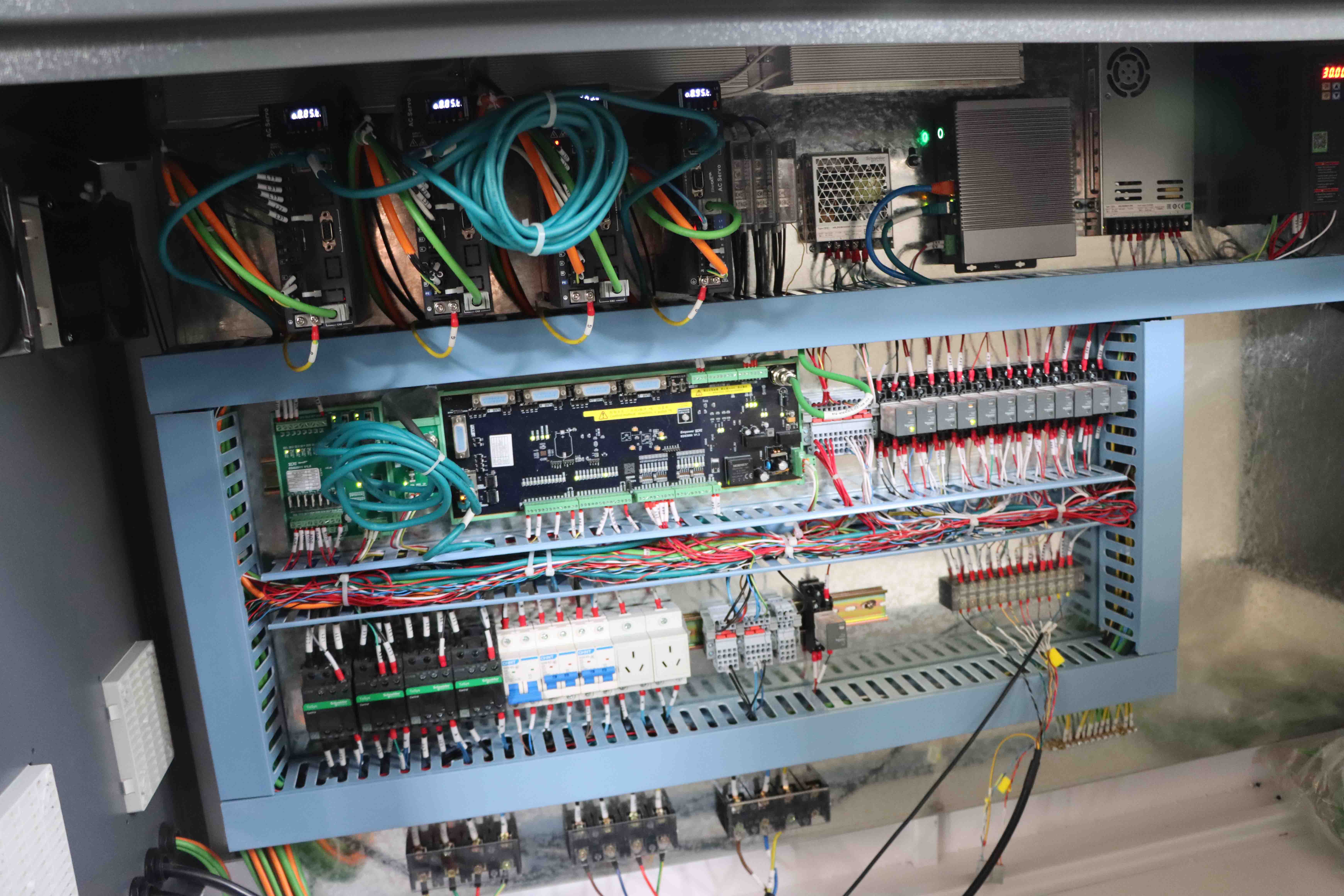

Fiber laser cutting machines use a high-intensity laser beam to melt, burn, or vaporize materials. Brass, being a copper-zinc alloy, has high thermal conductivity and reflectivity, which can make laser cutting more challenging compared to materials like steel or aluminum. However, modern Roclas fiber laser cutting machines are equipped with advanced technology to handle brass efficiently.

Key Considerations for Cutting Brass with a Fiber Laser

1. Laser Power & Wavelength

- Brass reflects more laser light than steel, so higher power (typically 500W to 1kW or more) is recommended for clean cuts.

- A 1µm wavelength fiber laser is more effective for brass than CO₂ lasers, as it provides better absorption.

2. Assist Gas Selection

- Nitrogen (N₂) is commonly used for cutting brass to prevent oxidation and achieve a clean edge.

- Oxygen (O₂) can be used but may cause discoloration and rough edges.

3. Cutting Speed & Focus

- Slower cutting speeds improve edge quality but increase processing time.

- Proper focal length adjustment ensures precise cuts without excessive burring.

4. Material Thickness

- Fiber lasers can cut brass up to 4-6mm effectively. Thicker sheets may require multiple passes or alternative cutting methods.

Advantages of Using a Roclas Fiber Laser for Brass Cutting

- High Precision – Delivers smooth, burr-free edges ideal for intricate designs.

- Speed & Efficiency – Faster than traditional mechanical cutting methods.

- Minimal Heat Distortion – Reduces warping, maintaining material integrity.

- Automation Compatibility – Works seamlessly with CNC systems for repeatable accuracy.

Applications of Laser-Cut Brass

- Electronics – Precision components like connectors and terminals.

- Jewelry & Decorative Items – Intricate engravings and custom designs.

- Automotive & Aerospace – Durable, corrosion-resistant parts.

Yes, a fiber laser cutting machine can cut brass effectively when using the right settings. Roclas fiber lasers provide the power, precision, and reliability needed for high-quality brass cutting across various industries. For optimal results, adjust power, assist gas, and cutting parameters based on material thickness and desired finish.

If you're looking for a high-performance fiber laser cutter for brass, explore Roclas' advanced laser solutions today!