Introduction

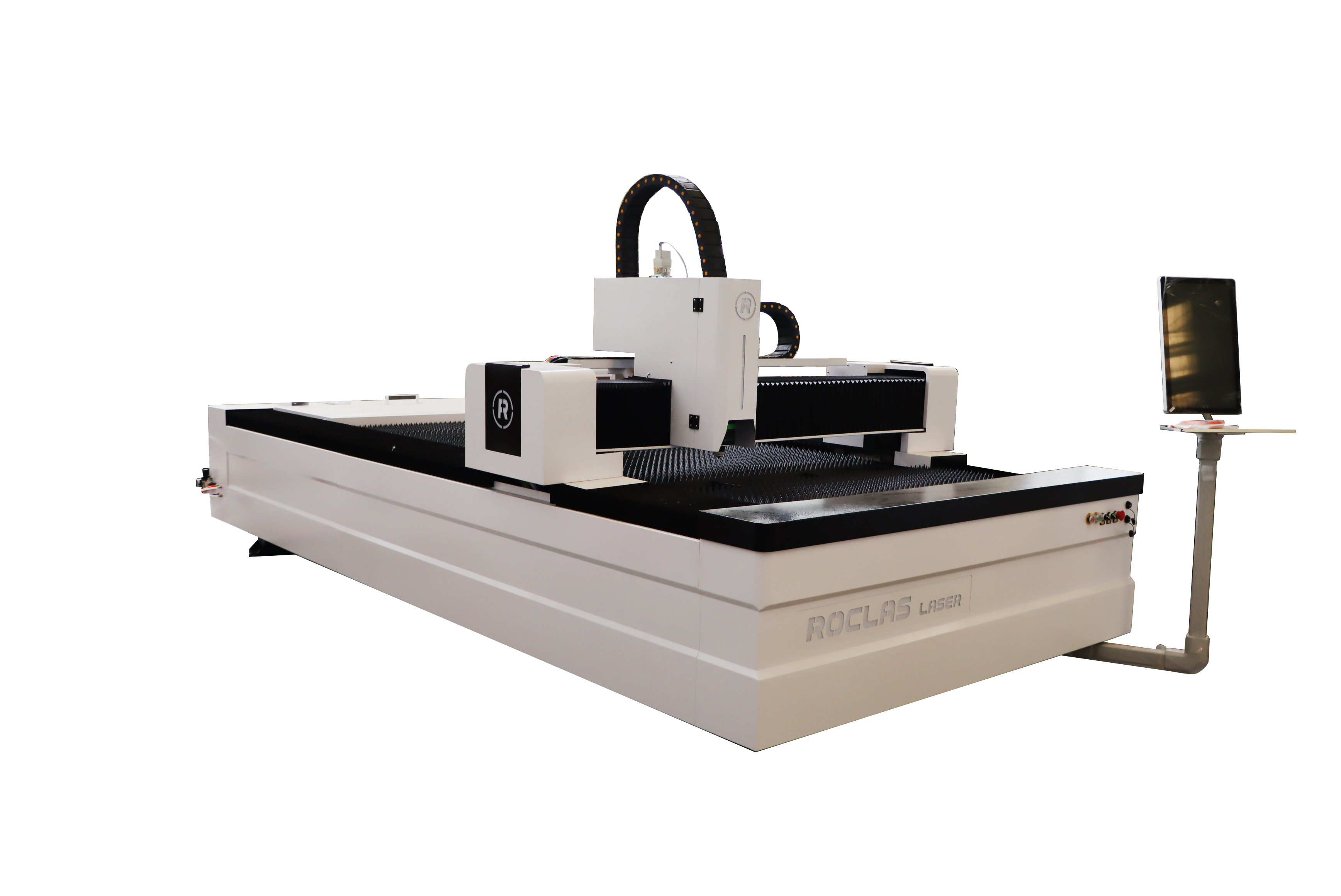

Stainless steel is one of the most widely used materials in industries such as automotive, aerospace, medical, and construction due to its durability, corrosion resistance, and aesthetic appeal. However, cutting stainless steel with precision requires advanced technology, and Fiber laser cutting machines have emerged as the most efficient solution. Roclas, a leading brand in CNC engraving and laser cutting, offers high-performance fiber laser cutting machines that deliver exceptional results on stainless steel.

Why Choose Fiber Laser Cutting for Stainless Steel?

1. Superior Precision & Clean Cuts

Fiber lasers produce a highly concentrated beam that ensures smooth, burr-free cuts with tight tolerances. Roclas machines utilize advanced optics and motion control systems to achieve micron-level accuracy, making them ideal for intricate designs and industrial applications.

2. High Speed & Efficiency

Compared to traditional cutting methods (plasma, waterjet, or mechanical cutting), fiber laser cutting machines operate at significantly higher speeds without compromising quality. Roclas machines optimize cutting parameters to reduce production time while maintaining energy efficiency.

3. Minimal Material Waste & Cost-Effectiveness

The non-contact cutting process of fiber lasers minimizes material deformation and waste. Roclas systems feature intelligent nesting software to maximize material usage, lowering operational costs for businesses.

4. Versatility Across Thicknesses

Whether you're working with thin sheets (0.5mm) or thicker plates (up to 30mm), Roclas fiber laser cutters adjust power settings automatically to ensure consistent performance. Nitrogen or oxygen assist gases further enhance cut quality for different stainless steel grades (e.g., 304, 316).

Roclas Fiber Laser Cutting Machines Key Features

- High-Power Fiber Laser Source (500W-20kW+) – Ensures deep penetration and smooth edges.

- Automated Feeding & Unloading Systems – Streamlines workflow for mass production.

- AI-Powered Control Software – Simplifies operation with real-time monitoring and error correction.

- Eco-Friendly Design – Reduced energy consumption and fume extraction systems comply with industrial safety standards.

Applications of Laser-Cut Stainless Steel

- Architectural Elements (elevator panels, decorative screens)

- Medical Devices (surgical tools, implants)

- Automotive Parts (exhaust systems, brackets)

- Consumer Electronics (smartphone casings, appliance components)

Conclusion

For businesses seeking high-speed, precise, and cost-effective stainless steel cutting, Roclas fiber laser cutting machines provide the perfect solution. With cutting-edge technology and robust engineering, Roclas ensures superior performance for industrial and artistic applications.

Upgrade your production line with Roclas today—where innovation meets precision!

(Word count 520)