When investing in a Fiber laser cutting machine, understanding the price is crucial for making an informed decision. The cost of these machines varies significantly based on several factors, including power, brand, features, and application requirements. In this article, we’ll explore what influences the fiber laser cutting machine price and why Roclas stands out as a top choice for quality and affordability.

Key Factors Affecting Fiber Laser Cutting Machine Price

1. Laser Power (Wattage)

The power of the laser source is a primary cost determinant. Machines with higher wattage (e.g., 1000W, 2000W, or 6000W) cut thicker and denser materials faster but come at a higher price. Lower-wattage models (e.g., 500W–1000W) are more affordable and suitable for thin sheet metal cutting.

2. Cutting Area (Workbed Size)

Larger workbeds (e.g., 4m x 2m or 6m x 3m) accommodate bigger sheets, increasing productivity but also raising the price. Smaller machines (e.g., 1.5m x 3m) are budget-friendly for small workshops.3. Brand and Quality

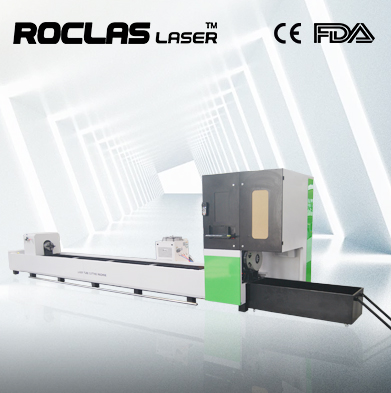

Reputable brands like Roclas offer reliable machines with advanced technology, durable components, and excellent after-sales support. While premium brands may have higher upfront costs, they ensure long-term efficiency and lower maintenance expenses.

4. Automation Features

Automated loading/unloading systems, CNC controls, and AI-assisted cutting increase precision and productivity but also add to the price. Semi-automatic or manual machines are more affordable but require more operator intervention.

5. Material Compatibility

Machines optimized for cutting stainless steel, aluminum, or copper may have specialized components (e.g., high-frequency lasers, nitrogen assist gas systems), affecting the price.

Why Choose Roclas Fiber Laser Cutting Machines?

Roclas provides high-performance fiber laser cutting machines at competitive prices, ensuring excellent ROI. Key advantages include

- Precision & Speed Advanced laser sources ensure smooth, burr-free cuts with minimal waste.

- Energy Efficiency Lower power consumption compared to CO₂ lasers.

- Durability Robust construction with high-quality optics and motion systems.

- After-Sales Support Comprehensive training, maintenance, and spare parts availability.

Conclusion

The fiber laser cutting machine price depends on power, size, features, and brand reputation. Roclas offers a perfect balance of affordability, performance, and reliability, making it an ideal choice for businesses seeking top-tier laser cutting solutions.

For the best fiber laser cutting machine price without compromising quality, explore Roclas’ range today!