Introduction

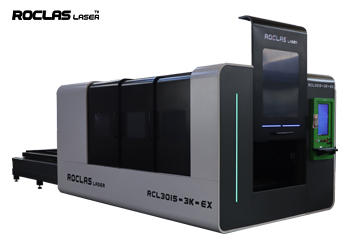

Laser beam cutting systems have revolutionized modern manufacturing, offering unparalleled precision, speed, and versatility. Whether for industrial metal fabrication, automotive parts, or intricate artistic designs, these systems deliver exceptional results. Among the leading brands in this field, Roclas stands out with its cutting-edge technology, reliability, and customer-focused solutions.

What Are Laser Beam Cutting Systems?

Laser beam cutting systems use a high-powered laser to cut, engrave, or etch materials with extreme accuracy. The laser beam is generated through a resonator and directed via mirrors or fiber optics to the cutting head, where it melts, burns, or vaporizes the material. These systems are widely used in industries such as aerospace, automotive, electronics, and signage due to their ability to handle metals, plastics, wood, and composites.

Types of Laser Cutting Technologies

1. Fiber Laser Cutting – Ideal for metals like steel, aluminum, and copper, fiber lasers offer high energy efficiency and low maintenance.

2. CO2 Laser Cutting – Best suited for non-metallic materials such as acrylic, wood, and leather.

3. NdYAG/NdYVO4 Lasers – Used for specialized applications requiring high peak power.

Among these, Roclas Fiber laser cutting machines are renowned for their superior performance, durability, and cost-effectiveness.

Key Advantages of Roclas Laser Beam Cutting Systems

1. Precision & Speed – Roclas machines deliver micron-level accuracy, ensuring clean cuts with minimal kerf width. Their high-speed capabilities boost productivity.

2. Energy Efficiency – With advanced fiber laser technology, Roclas systems consume less power while maintaining high output.

3. Low Maintenance – Unlike CO2 lasers, Roclas fiber lasers have no mirrors or gas tubes, reducing downtime and operational costs.

4. Versatility – From thin sheets to thick plates, Roclas machines handle a wide range of materials effortlessly.

5. User-Friendly Software – Intuitive CNC controls and automation features make operation seamless, even for beginners.

Applications of Roclas Laser Cutting Systems

- Metal Fabrication – Precision cutting of stainless steel, carbon steel, and aluminum for industrial parts.

- Automotive Industry – Manufacturing exhaust systems, chassis components, and intricate designs.

- Electronics – Producing micro-components with high accuracy.

- Art & Decor – Creating detailed engravings on wood, acrylic, and other materials.

Why Choose Roclas?

Roclas is committed to innovation, quality, and customer satisfaction. Their laser cutting systems are backed by robust engineering, excellent after-sales support, and competitive pricing. Whether you're a small workshop or a large-scale manufacturer, Roclas provides tailored solutions to meet your needs.

Conclusion

Laser beam cutting systems are indispensable in modern manufacturing, and Roclas leads the industry with its advanced technology and reliable performance. By investing in a Roclas machine, businesses can achieve higher efficiency, lower costs, and superior cutting quality.

For more details, visit Roclas today and discover the future of laser cutting!